- 会 社 名

- Nidec Machine Tool Corporation

- 代表者名

- 取 引 所

- 所 在 地

- 問合せ先

- 電 話

- The new models will shorten non-machining time by 50% compared with conventional models (a world-leading level).

- The models will showcase their first completely automated inline measurement at JIMTOF2024.

Nidec Machine Tool Corporation (“Nidec Machine Tool” or the “Company”), a Nidec Group company, today announced that it has developed ZFA160 and ZFA260, both global-standard gear grinders to meet the global needs for high-precision gear machining. The Company will launch the two new models, each made for a different gear size range, after exhibiting them at this year’s Japan International Machine Tool Fair (JIMTOF2024), which will be held from November

5 – 10, 2024.

In response to the rising needs for high-precision, stable, and high-performance production of gears for electric vehicles’ transmission mechanisms and robots’ speed reduction mechanisms, Nidec Machine Tool will utilize the aforementioned event to introduce their machines’ capabilities, while performing demonstration of inline work-piece (units to be machined) measurement for complete automation, and of automated carry-in and take-out operations by TR-20W, a carriage-type robot system by Takisawa Machine Tool Co., Ltd., to propose total solutions for gear machining.

The two ZFA series gear grinders to be launched this time are designed to perform high-speed and high-precision finish machining on gears. The two models are each designed for a different gear size range, with ZFA160 capable of handling gears with an external diameter of up to 160mm, and ZFA260 accommodating gears with an external diameter of up to 260mm. Capable of meeting the increasingly sophisticated the users’ needs, both ZFA160 and ZFA260 can massproduce gears with a gear accuracy level equivalent to ISO 3 (JIS level N3).

In regard to their high-speed machining performance, the two models, with a newly developed twin-table*1 structure and high-speed rotary performance, boast a word-shortest non-machining time of 4 seconds, a 33% improvement from ZE16C, the current model, and a 50% improvement from ZE26C. In addition, to secure a stable high-precision machining, ZFA160 and ZFA260 employ stiffer work-table structures, grinding stone heads, and dress*1 units among others. Furthermore, the models’ main axis structures were made to endure high-speed machining, while, for theirmachines’ heads (boards to comprise the machines’ main units), a thermostable material (mineral cast*2), which suppresses vibration from high-speed machining and heat-caused dimension change, was adopted to stabilize accuracy during high-volume production (O.B.D.*3 variation range during consecutive machining: app. 10μm).

ZFA160 and ZFA260 boast features for machining EV gears as well, such as “simultaneous double-tooth flank bias adjustment,” a function to suppress distortion on flanks, and “low-noise machining,” which reduces periodical asperity on tooth flanks, among many other high-precision machining technologies.

Furthermore, as part of actions to curb environmental load, the users of the two latest models can select a circular, filter fabric coolant tank to process sludge- and coolant-containing waste from a machining process. This feature enables ZFA160 and ZFA260 to discharge zero amount of sludge-containing paper filter, helping them generate less industrial waste than other models.

As automobiles become electrified, quieter, more fuel-efficient, and produced at low cost, there is a globally growing need for high-precision finish of gears and the mass production of precision gears. In addition, as the demand for a variety of reducers for high-performance robots increases, the public are increasingly interested in gear grinders capable of high-speed and high-precision machining.

As Japan’s leading geared machine tool manufacturer, Nidec Machine Tool stays committed to developing global standard machines equipped with automation, manpower saving, and ecofriendly technologies, to propose gear machining-related total solutions to the global market.

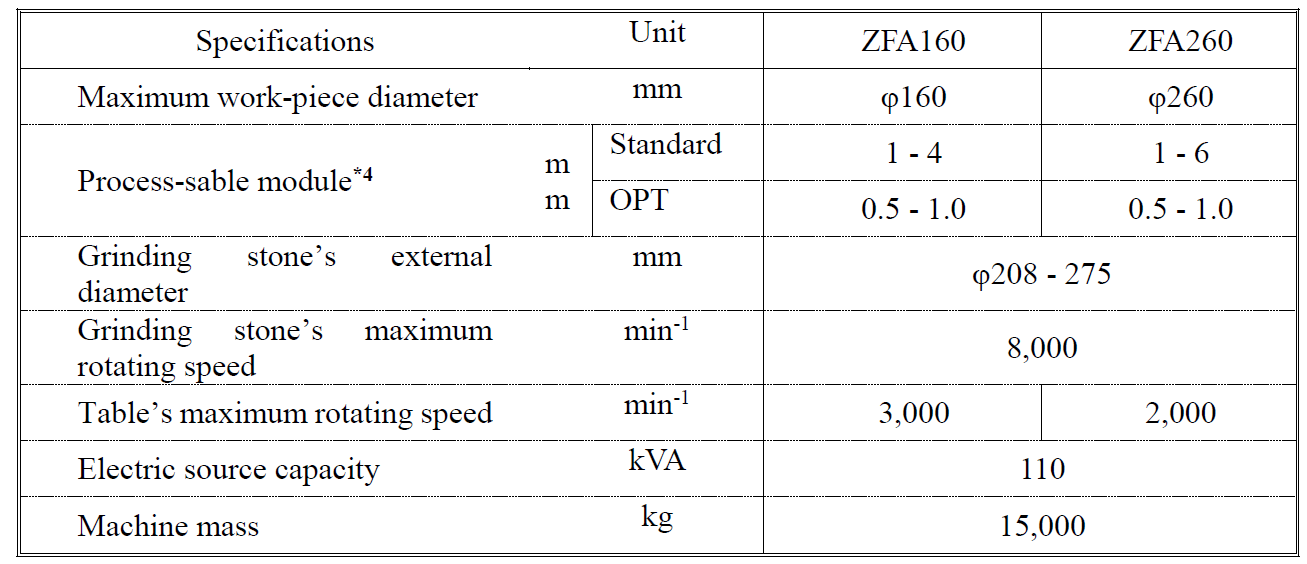

■ Main specifications of gear grinding machines ZFA160 and ZFA260

*1. By installing two work-accommodating tables onto a machine, one can set up machining on one side while machining is underway on the other side.

*2. A component or material whose natural rock, etc. has been solidified with resin. This material has a low thermal conductivity, is hard to be affected by temperature change, and has a high vibration damping. In addition, unlike cast metals, there is no manufacturing process that discharges a large amount of CO2.

*3. An index that indirectly represents the precision of a gear’s pitch circle. “O.B.D” stands for “over ball diameter.”

*4. Module: A value that represents the size of a gear’s teeth (i.e., the pitch circle’s diameter (mm) divided by the number of teeth).