Service Robots

Smooth and Precise Robotic Joints

Mechanisms for Realizing Smooth and Precise Robot Joint Movements

The Nidec group possesses technology for smooth control of joints and rotating parts through use of slip rings and potentiometers, among others.

Many types of robots are required to meet high reliability requirements. Logistics robots, for instance, are expected to operate continuously twenty-four hours a day, 365 days a year, while nursing care robots or power assist suits need to be highly durable and sturdy.

For these types of robots, regular lead wires used for joints and rotating parts run the risk of breaking and snapping due to repeated bending. Also, in order to perform precise movements, it becomes necessary to accurately sense and control these joints and rotating parts.

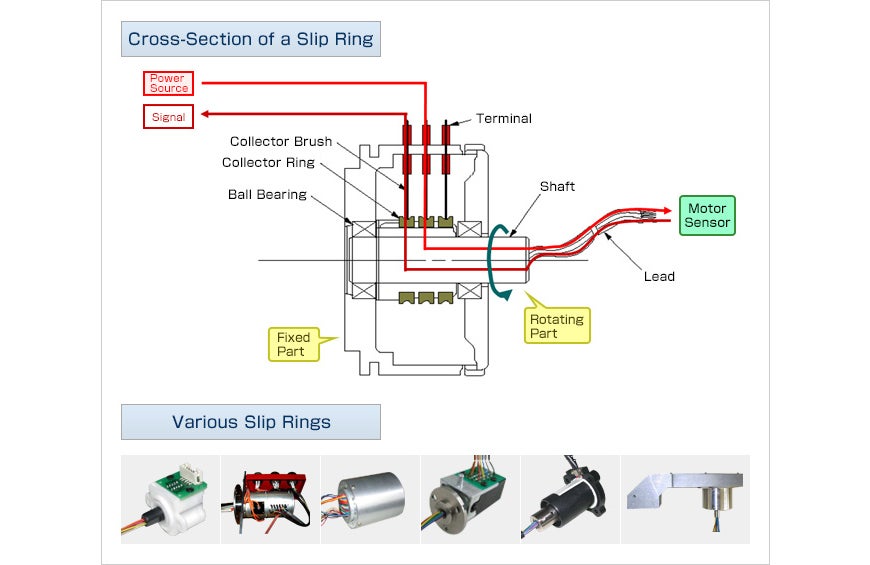

Slip Rings

Regular lead wires risk breaking due to metal fatigue associated with torsion and entanglement inside the shafts of the joints and rotating parts of robots. This risk, however, can be eliminated by using the slip rings manufactured by NIDEC INSTRUMENTS. Furthermore NIDEC INSTRUMENTS’s slip rings allow data transmission in addition to supplying power.

Potentiometers

Potentiometers* are used to detect angle of rotation and position with high precision. Conductive plastic type potentiometers, in particular―with their extremely high (theoretically infinite) resolution―due to having minimal sliding friction coupled with characteristics such as long life, low torque and low noise help realize accurate position detection and motion control in joints used for service robots.

- *Our potentiometers are manufactured by NIDEC PRECISION, NIDEC PRECISION Electronics and NIDEC ADVANCED MOTOR.