2-2-2. Structure and Application of Brushless DC Motors

Inner Rotor Type

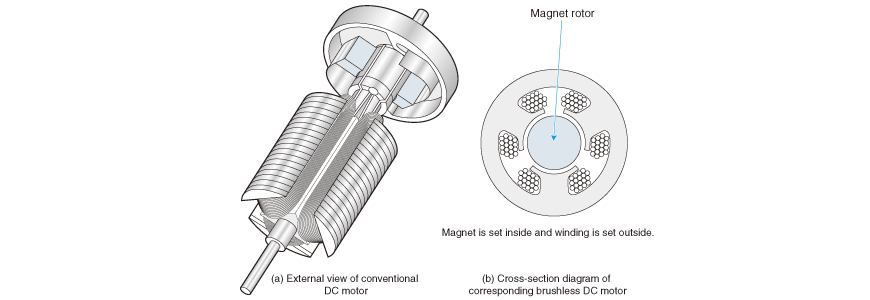

There is a brushless DC motor called the inner rotor type that has the magnet inside acting as the rotor while the winding is arranged outside as the stator.

As shown in Fig. 2.23, this structure is the reverse of that of conventional DC motors. Compared to the DC motor, this type of motor has the following features:

- ・Small moment of inertia of the rotating shaft

- ・Ability to downsize the main unit

- ・High heat dissipation efficiency

However, to obtain a high magnetic flux density using small magnets, high performance magnets must be used.

Creating a large number of coils inside the stator is a more difficult task than winding coils outside the rotor. For this reason, an inner rotor type motor is currently used for applications that require a compact and high-output motor with superior dynamic characteristics.

Outer Rotor Type

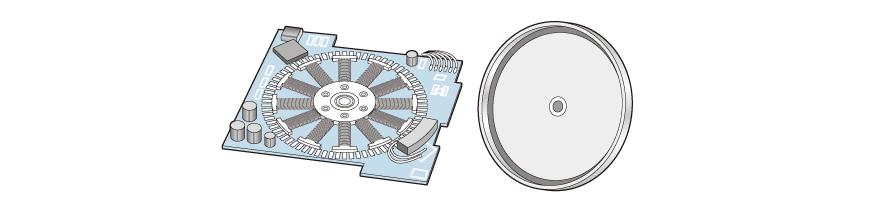

Converse to the inner rotor type, there is a type of motor that has the coil arranged inside and the magnet that is to be rotated arranged on the outside. This type is called the outer rotor type (Fig. 2.24).

Compared with the inner rotor type, the rotating shaft of the outer rotor type motor has a greater moment of inertia. However, due to the fact the magnet does not have to be downsized, the ease of coil winding becomes a structural advantage.

Outer rotor type motors are adopted for hard disk drive motors, etc.

Other structural varieties include a thin motor that has a flat rotor with the coil directly installed on the printed circuit board.

This type is adopted for floppy disk drive motors, brushless fans, etc.

Coil Structure

Basically, the number of coils in an ordinary brushless DC motor is a multiple of three. Regarding the coil winding method, there are two types: the distributed winding method shown in the preceding Fig. 2.22, and the concentrated winding method as shown in Fig. 2.24 and Fig. 2.25.

In the early days of brushless DC motors, distributed winding type motors were used, but concentrated winding type motors are generally used these days.

A rotor magnet has an N-pole and an S-pole. A rotor that has one N-pole and one S-pole is said to have two poles.

If a rotor has NSNS poles, it has four poles. The more coils or rotor magnetic poles there are, the easier the process of fine control becomes.

A typical servo motor has 9 or 12 coils, and a rotor that has about 8-poles.

Some large outer rotor type motors have more magnetic poles and coils.