2-1-4. DC Motor With a Core Slot

Now for an examination of a motor with an iron core.

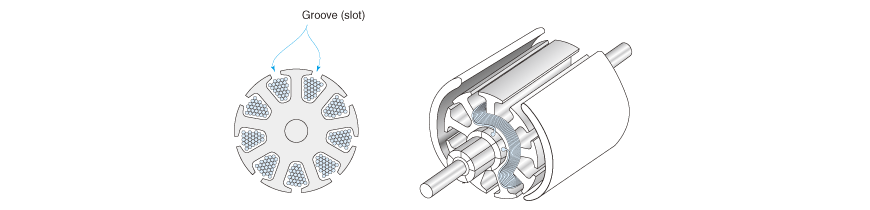

The rotor of the type of DC motor we usually see has a lamination of slotted thin steel sheets (silicon steel plates), and the coil is inserted into the core slots.

The minimum number of slots required to allow the rotor to rotate from any angle is three. This is a structure that we have become familiar with through the use of motors used in models.

If there are only a small number of slots, there will be a difference in the torque generated depending on the rotational position. The greater the number of slots and coils, the smoother the rotation will be due to the reduction of torque non-uniformity (fluctuation). For this reason, higher end motors have more slots and many coils.

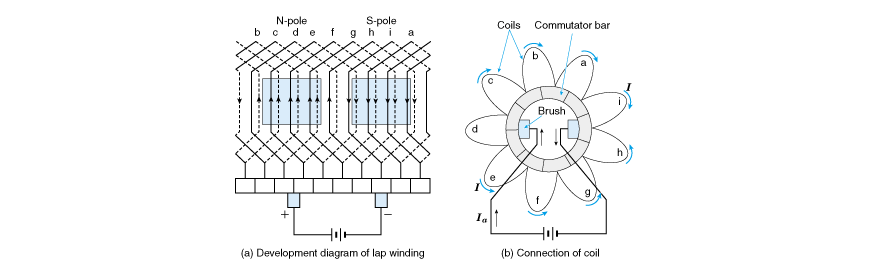

With a motor that has many slots, the coils are cross-coupled as Fig. 2.15 shows.

This winding method is called lap winding. Also, the method of winding a coil between neighboring slots is called concentrated winding, and this method has been adopted for stepping motors and brushless DC motors.

When a rotor coil is expanded, we will see that the coils are connected to the commutator like flower petals are to the calyx as Fig. 2.16 (b) shows. As the figure is self-explanatory, current from the terminal flows by dividing the group of coils into two. This structure of the DC motor enables some windings to be sequentially switched over as the rotor rotates.

Also, coil switching is implemented in the intermediate position of a magnet in which no magnetic force is working (neutral belt) so that no counter-electromotive force is generated. Adopting such a structure can reduce the brush loss that occurs when the coil current is switched (during commutation).

Another method used to moderate torque non-uniformity is to provide slots that are askew to the direction of rotation.

These slots are called skews or inclined slots. A skewed rotor is shown in Fig. 2.17.

<Short column> Coil and winding

In the field of motors, a wire wound around a pole is generally called a "coil", and the state in which respective coils are mutually connected is called a "winding". In this book, we will follow this convention and use these terms accordingly.