More for Society

Make More Efficient Products

Motors consume less power as their energy efficiency improves. A 10-percent improvement in motor efficiency would make 100 nuclear power plants redundant, while EVs could run 1,000km with a single battery charge, robot cleaners could clean much larger rooms, and refrigerators and air conditioners would require less electricity. How can we make them happen? To achieve greater chances, we need to think of the efficiency of not just motors but also that inverters, gears, and bearings as well. This is the prime reason why Nidec handles not just motors but the entire traction motor system, and not just fans but the entire vacuum cleaner device.

Nidec’s Solutions with High-efficiency Products

Low-noise, low-power-consumption motor for air purifiers

Diverting a technology for solving issues with server rooms to create a comfortable atmosphere.

A minuscule vibration motor that creates realistic tactile sense

Utilizing its compact motor-based knowhow, Nidec developed a minuscule vibration motor that creates a realistic tactile sense.

Compact and light brushless DC motor for cordless vacuum cleaners

Utilize the brushless DC motor’s competitive advantages to offer motors for light and high-suction cordless vacuum cleaners.

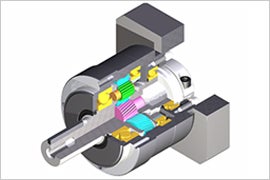

EV Traction Motor System E-Axle

The product that combines the Nidec Group’s technologies to work as an EV’s “heart”

Automated Transportation Robot Drive Module

Generate synergies within the Nidec Group to develop a high-efficiency drive module.

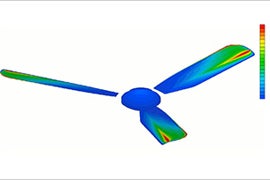

Development of Ceiling Fans and Outlook for the Future

At Nidec, we are expanding our capabilities to include ODM services focusing on ceiling fan components, units as well as finished and ready-to-use products—poised for global expansion, starting with the Indian market.

Brushless DC Motors, Blowers and Gear Units for Vacuum Cleaners

Modules that combine the superior capabilities of brushless DC motors with blowers, gears and other components

Motor For Cleaning Robot

Nidec provides highly efficient, small and light, low-noise and long-life motors. In addition, we are ready to offer design work up to the point where the motor is connected to the wheel. Motors inclusive of the unit design are available for customers.

DCT Motors

Nidec develops and manufacturers superior DCT motors and contributes to improving the environmental performance of automobiles.

Electric Oil Pumps

The Nidec group develops electric oil pumps necessary for hybrid-mode driving and idling stop systems—the keys to lower fuel consumption.

Integrated Electric Power Steering Motors and ECUs

The Smallest and Lightest Class of Power Packs in the World.

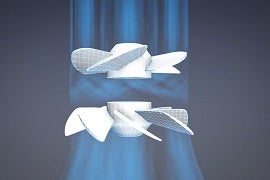

Integrated Brushless DC Motor and Fan Blade Units for Electric Fans

The trend of reduced power-consumption and increased functionality has reached the electric fan market. Nidec develops products that contribute to smaller and lighter high-functionality electric fans with a wide range of settings and modes.

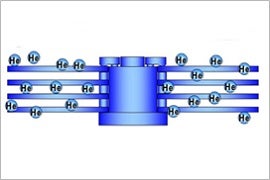

Helium-Filled Hard Disk Drives

HDDs filled with helium have improved read/write precision and lower power-consumption due to minimized disk vibration caused by drag.

Next-Generation Motor Control Technology

Nidec has succeeded in the development of control technology that enables position control of brushless DC motors with a precision rivaling that of HP stepper motors. This new technology paves the way for more efficient, lightweight and compact products in a variety of fields including multifunction printers.

Image-stabilizing mechanism, TiltAC

Motors that can withstand the pressure of ocean depths of 4000m developed for submarine cable burying ROVs.

Smart Microgrid Solutions

Providing stable energy for a remote village in the Andes mountain range through integration of photovoltaic power generation, energy storage and a diesel generator.

Nidec’s Technology to Create High-efficiency Products

Brushless Motors

Nidec has a significant amount of experience in producing brushless DC motors featuring energy saving, long life, low noise, compact size and light weight.

Solutions Centered on Brushless DC Motors

Optimally designed modules combining motors with fans, blowers, pumps, gears and controllers

Rapid Prototyping

Exceeding the Needs of our Customers with Shorter R&D Cycles and Reduced Costs

Nidec's Technical Capabilities CAE Technology Developed In-House

At Nidec, we utilize original modeling technology and analysis software developed in-house to optimize the design of our fluid dynamic bearings

The Advanced CAE Technology behind our Optimally Designed Modules and Units

Coupled analysis and other advanced CAE tools cut down on development times and make development of advanced modules and units easier.