Implemented Solutions

A minuscule vibration motor that creates realistic tactile sense

Utilizing its compact motor-based knowhow, Nidec developed a minuscule vibration motor that creates a realistic tactile sense.

- NEEDS

- Create a realistic tactile sense for digital devices

- SOLUTION

- Defy conventional thinking to develop the world’s smallest, 3mm minuscule vibration motor.

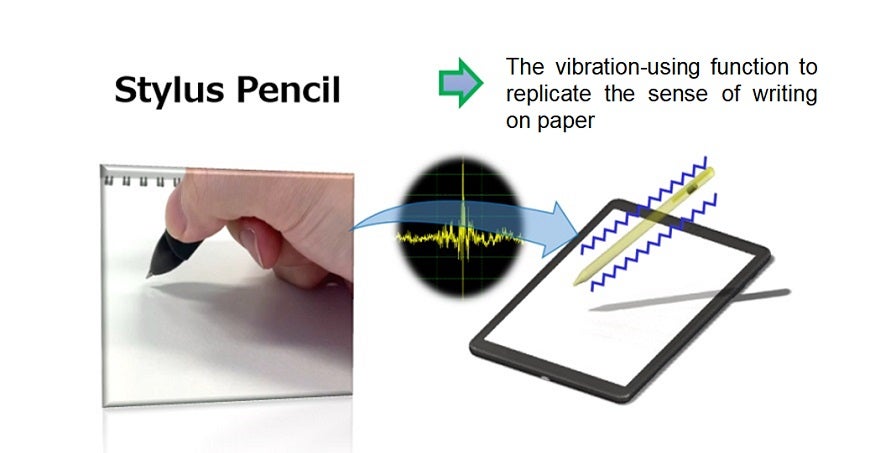

A minuscule vibration motor that vibrates inside a pen to replicate a tactile sense

At present, almost all commercially available smartphones are equipped with a built-in vibration device that vibrates to create a tactile sense. When vibrating, the motor makes users feel as if they were pressing a button instead of simply touching an icon on a panel. In recent years, partially due to the spread of AR technology typified by Smart Goggles and Smart Gloves, the needs are rising year by year for technologies that create a realistic sense in such digital devices.

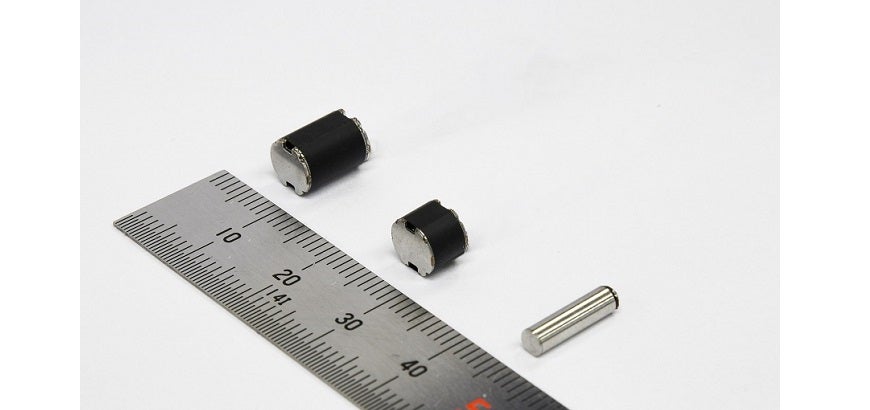

To meet such needs, Nidec developed two types of minuscule vibration motors: The first type is an extra-fine, cylindrical vibration motor with a diameter of 3mm and a height of 10.3mm. This motor can be installed into a stylus pen with a diameter of 6 to 8mm. The motor, which replicates the vibration of a pen’s edge writing words on a sheet of paper, creates a tactile sense to feel as if the user were writing on paper with a stylus pen.

The second type is a thin, and once again cylindrical vibration motor with a diameter of 6.55mm and a height of 5.0mm. This motor is intended to be built into AR goggles and other products. These two types of motors have common features of being minuscule enough to defy the conventional wisdom, and being energy-efficient to consume only about one-fiftieth of the electricity required for a vibration motor installed in an ordinary smartphone.

Change the way to think to realize energy-efficient, minuscule-size motors.

These features are the results of creating their internal structures by defying conventional wisdom. Normally, several tenths of a millimeter of clearance is required for components inside a vibration motor to prevent component-to-component interference. The newly developed vibration motors, however, were able to be made so surprisingly minuscule by individual components being designed to interfere with each other. When contacting each other, those components will, of course, cause friction. Yet, by combining materials that reduce the friction, Nidec successfully developed this structure, which acquired sufficient reliability after an approximately 240 hours of drive test.

This structure, which will not affect the motor’s characteristics even after component-to-component contact, enabled us to minimize the dead space inside the motor, while greatly contributing to reducing electricity consumption. Coupled with the design of a high-efficiency magnetic circuit made based on our compact-spindle motor development, the extra-thin vibration motor’s electricity consumption is as low as 1.3mW. Due to their weight restrictions, stylus pens, AR goggles, and other products only have a limited battery capacity. Even with such a small battery, our motors can keep running for a sufficient length of time.

With the growing expectations for users to be able to user their own avatars online in the future, the level of attention is growing on wearable vibration motors, which create a pseudo-tactile sense. Their applications will continue to increase as they are used in medical and other fields. With its minuscule vibration motor, Nidec is poised to meet the needs of the expanding tactile technology.