Implemented Solutions

Thinner HDD Motor Design

Thinner Notebook PCs made possible by advances in HDD motor design

Thin PC design requires the use of thinner components, and Nidec, the global market leader in the HDD spindle motor market, supports the evolution of notebook PCs by providing thinner motors.

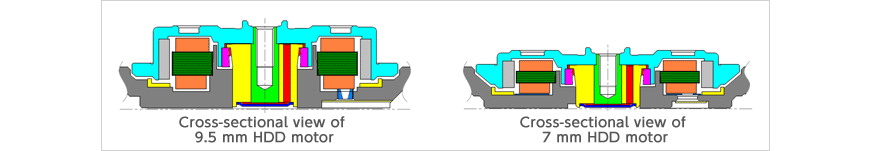

Currently, 7 mm thick HDDs are in mainstream use for notebook PCs. The thickness of the spindle motor built in to the HDD is 70% to 75% of the thickness of the disk drive, making the motors of 7 mm HDDs approximately 5 mm thick. The biggest barrier to successful thin motor design has been the assignment of sufficient space for magnetic circuits and bearings to support the rotor. If the magnetic circuit size is simply reduced, the desired magnetic force cannot be obtained. Also, the bearings around a shaft several millimeters in length must be rigid so that one or two 2.5" disks can be rotated at a constant speed of 5,400 rpm or 7,200 rpm. In other words, reduced size is not enough by itself. Performance must be maintained or even enhanced at the same time.

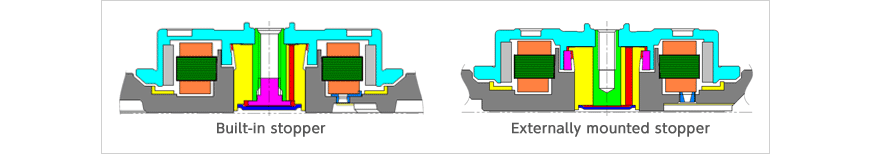

For example, motors for 9.5 mm thick HDDs that ruled the market before the advent of the 7 mm HDD initially used an internal stopper to keep the shaft in place. However, to build better products than the competition, we drastically changed the structure of our motors and relocated the stopper outside the shaft instead of developing a thinner internal stopper. In this way, we make changes to the very structure itself when necessary in order to build a basic structure that can be used for several generations. Doing so is one of our development strategies in the field of IT where evaluation speed is extremely fast.

The built-in stopper was moved to the outside of the shaft.

In addition to 7 mm thick HDDs that have been mass-produced since 2010, Nidec also possesses the capabilities to produce HDDs as thin as 5 mm. With a global market share of 80%, we supply our products on a global basis with a close eye not only on performance of individual products but also on the entire QCD process. We also plan for mass production even during the early product development stage, and consider product continuation to the next generation when making design decisions.