Implemented Solutions

Solutions for glass elevators

Expanding the range of applications for elevators

through implementation of compact drive systems

- NEEDS

- Adding an elevator to a building without constructing a dedicated machine room on the roof

- SOLUTION

- Compact hoists that can be placed inside the elevator shaft

Glass elevators offering pleasant and comfortable rides

Recently, glass elevators have become a common occurrence throughout cities around the world. When installed in public places such as railway platforms and concourses, these elevators provide a feeling of openness due to not obstructing visibility compared to conventional elevators. They provide passengers a more comfortable ride by reducing the feeling of being trapped in a closed space. At the same time, glass elevators also have an advantage when it comes to safety, since the interiors of the elevators are visible to security cameras and personnel. As a recent trend, these elevators have seen a surge of use in monumental structures around the world. Glass elevators are often included in renovations of historical buildings or construction projects in which special attention is paid to design. Making these elevators, with their many features and advantages, requires the application of a variety of technologies.

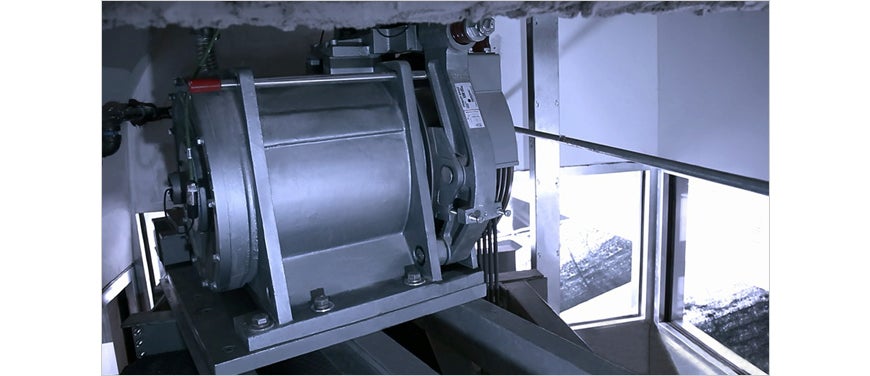

Small permanent magnet AC motors and gearless hoists eliminate the need for a machine room

When a glass elevator is installed in a historical building, for example, it is often the case that a dedicated machine room cannot be built on the roof of the building. This is where compact permanent magnet AC gearless hoist machines developed by Nidec KINETEK come into play. Through the use of rare earth permanent magnets, the motors can be made more compact while still maintaining the torque necessary to drive the elevator hoists. These smaller motors do not require reduction gears, allowing for more compact hoist machines which can be placed inside the elevator shaft, eliminating the need for a machine room on the roof. Furthermore the idea of using steel belts instead of the wire ropes traditionally used for elevators also contributes to the miniaturization of elevator equipment. The standards for elevators issued by the American Society of Mechanical Engineers (ASME) dictate that the hoist sheave size should be at least 40 times the diameter of the rope. A rope that is 12.7mm thick, for example, would require a sheave with a diameter of 508mm. However, by using a thin steel-coated belt instead of a wire rope, the sheave can be made smaller and still generate the friction / traction necessary, while being in compliance with the ASME standards.