NIDEC's Technical Capabilities

Electric bike (e-bike) motors

- NEEDS

- Eliminate troubles with e-bike motors.

- SOLUTION

- Utilize Nidec’s knowhow on a variety of motors to offer competitive high-quality motors.

Quality to beat the competition in the Chinese market of tens of millions of motors

While e-bikes are used in growing numbers in delivery and other businesses in Japan, there is already a market of several millions of them in China. The country’s urban areas have already seen small-size bikes, which are categorized as motorbikes in Japan, almost all replaced by e-bikes, almost all the bikes used in sharing and other businesses are electric. To achieve carbon neutrality and other purposes, Nidec is expanding its product lineup of drive motors for the e-bike market, which is expected to grow rapidly and globally going forward.

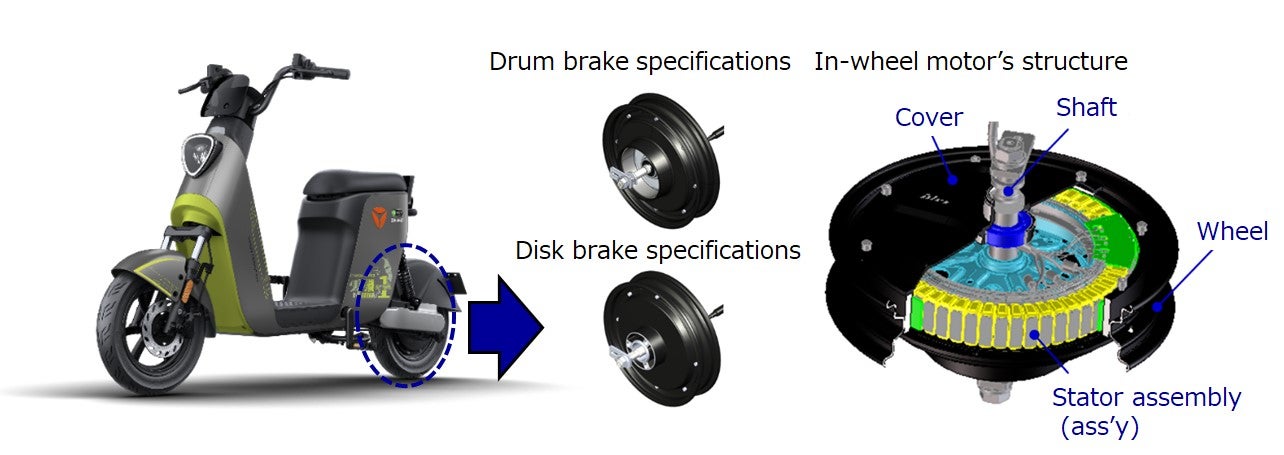

There are two types of motors for e-bikes: the center type, which is installed at the center of the vehicle’s body; and the in-wheel type, which is connected to the sides of the bike’s drive wheels and to the drive wheels. In-wheel motors are the mainstream in the Chinese market, where the majority of vehicles are compact. Nidec offers options of motors based on each vehicle’s size, output, and battery type.

In the highly competitive Chinese market, some motors are produced in a cost-prioritized way, and cause quality problems, which frequently cause trouble. While cases of those motors causing a fire or water leak, or deteriorating vibration or noise have been reported, Nidec-produced motors are reputed to be of wonderful quality, and used in high-end vehicles.

Supporting these motors’ quality is the knowhow owned by Nidec, the company that has handled a variety of motors, ranging from small precision motors to those used in EVs’ drive motor systems. Nidec boasts advantages over the competition in that the company thoroughly monitors its products’ quality in the production process, where, starting with the wire-winding section, the company uses sensors to detect heat generated, and controls current. Nidec prevents troubles by managing such systems comprehensively to suppress variation in quality to low levels.

Nidec inspects all units of motors it produces. With the automated manufacturing process, which is key in such inspections, the company minimizes increase in cost, and keeps its products’ prices competitive even in today’s highly contested market. By automating only areas directly linked to troubles, Nidec successfully achieved high quality of its products while keeping cost increase to a minimum, utilizing the company’s knowhow on producing a diversity of motors.

As China’s e-bike market reaches a maturity stage, there is no doubt that e-bikes will be introduced in other regions as well. The latest example of it is India, whose e-bike market is growing significantly, while similar trends are being seen in Indonesia, where its national government is issuing subsidies for the growth of the nation’s e-bike market.

In India, whose road conditions are worse than in China, higher-output motors are in demand. Nidec already has production bases in India as its e-bike market is expected to grow further, to respond to its local needs more directly than before.

Though a latecomer in the world of e-bikes, Nidec has already seen its motors growing competitive and evaluated highly in the fiercely competitive Chinese market. We are poised to utilize our company’s technological capability to contribute to carbon neutrality, while leading the world’s e-bike market.