Implemented Solutions

DCT Motors

Nidec has developed a DCT system to reduce energy use, realize high performance, and develop a driving motor that contains all base system functions.

Development in the automobile industry is focused on reducing energy use and environmental impact. In such flow, electrification of automobiles is advancing rapidly, electric power steering system and oil pumps are becoming more popular, and a new method has been introduced to power transmission systems, which is the core function of automobiles.

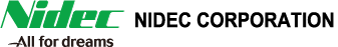

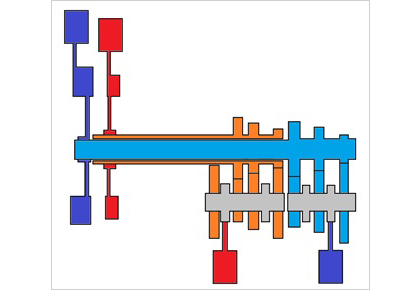

Among the automotive transmission systems, the DCT (Dual Clutch Transmission) has attracted the attention. The DCT has two systems of odd and even-numbered gears and clutches, and these two systems are alternatively engaged. Therefore, the time to change the gear is very short when shifting up or shifting down. Also, the DCT does not lose power due to the slipping of the torque converter although it occurs in conventional AT (Automatic Transmission) systems. The DCT has a feature that greatly improves fuel efficiency. In the situation in which users are aware and the automobile industry is working to improve fuel efficiency and reduce environmental impact, the DCT has been adopted and its use is rapidly spreading not only to passenger cars and commercial vehicles such as buses and trucks, but also to motorcycles.

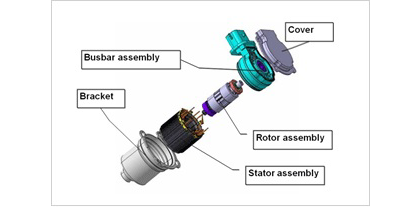

There are two types of DCTs: the electro-hydraulic system that rotates the hydraulic pump using the motor and switches the hydraulic system using the electromagnetic direction control valve, and the pure electric system that drives a certain point directly using the motor. The former has cost advantages, and the latter has superior efficiency and response. However, the pure electric system has a motor that drives four points, that is, two clutches of the clutch and gear system, and two shift selectors. A compact and high-output motor is essential to fit into small engine compartments. Also, the electric current must always flow through the motor when the clutch is engaged. Because the motor itself heats up and the heat is transferred from the engine, the temperature can increase and certain measures are required to be taken against the heat.

To reduce the amount of heat generated by the motor, we need to wind the copper wires as thick as possible. And the higher output of the motor depends on how many wires are wound. We adopted the divided cores for DCT motor and maximized the space utility between cores. We had to consider the heat measures and the implementation of electronic circuits that were made as compact as possible, and carefully select grease that could guarantee the operation from low temperature range to high temperature range. In addition to heat measures, we had to guarantee the vibration resistance, waterproof and rust prevention performance that is specific to automobiles. In the future, we will develop products that have better performance and cost effectiveness to expand our business while meeting the needs in the automobile field where more and more electric components, such as (to give an example other than DCT motors) motors for the idling stop function, are employed.