Implemented Solutions

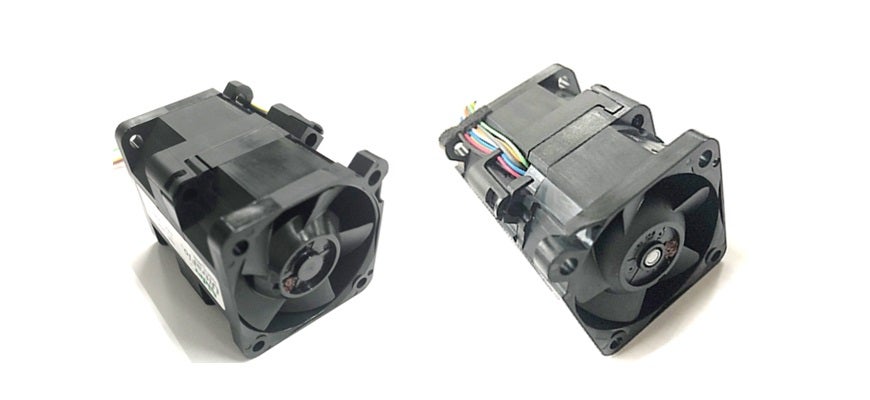

Air-cooling fan that respond to thermal migration in a datacenter

- NEEDS

- Please develop cooling fans that are optimum to our company’s servers.

- SOLUTION

- Supply customized products that make the best use of technological capability based on the collaboration from the design phase

Cooling fans – The major contributor behind the scene in the age of big data – Key to servers’ stable operations server

Datacenters, where racks of piles of servers are in use, are the major contributors that support the digital society behind the scene. Like PCs, servers are installed with CPUs and HDDs. However, used by a number of clients around the clock, servers are required to be significantly more reliable, better in performance, and scalable than PCs. This is why servers are equipped with multiprocessors, redundant electric power sources, and fans among others. Additionally, based on today’s demands for processing, to the best extent possible, a large volume of data on a specific floor of a datacenter, devices are installed in high density in each server.

This is why, to cool servers and protect them from thermal runaway, fans are required to have special performance capabilities. Since developing its first server fans in 2000, Nidec has been enjoying a high reputation for the products’ air volume and reliability, and customizability, which derives the maximum efficiency based on the actual product’s specifications.

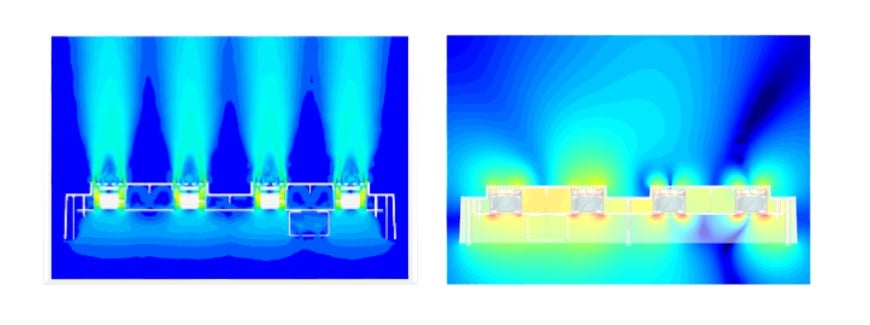

Supplying high-air-volume, low-noise motor cooling fans based on excellent development capabilities and CAE technical skills

The air volume of a product is, in general, determined by its rotational frequency. A PC’s fan typically rotates approximately 5,000 times per minute, while a server’s fans rotates 30,000 times per minute, about six times a PC fan does. Though one can increase a motor’s rotational frequency by making the motor larger; however, doing so would narrow the path of the wind, and the air volume would not increase effectively. At Nidec, utilizing the product development and manufacturing knowhow cultivated so far, we successfully developed compact and yet high-power brushless DC motors. By focusing on every single detail of their blades’ shapes and directions as well, we provide cooling fans that meet strict specifications requested by our customer companies.

In addition, to deliver the wind to the inside of the server, where CPUs and other components are installed in high density, static pressure (i.e., the power to push surrounding elements when the wind is not blowing) is considered important, together with the airflow. A contra-rotating propeller fan, with two fans connected in series, is used to generate a high static pressure. The two axial fans counter-rotating from each other are located in series, thus keeping the wind from spreading by the traversing force, and creating a straight wind current. At Nidec, we use a supercomputers to analyze and simulate wind flows comprehensively, and quickly identify structures that secure both high wind high static pressure, for our product development.

Contributing to the development of high-performance servers based on a customer-friendly joint development system

Since the fan motors has a high static pressure, the wind will start flowing backwards in its flow path once a fan malfunctions. This will quickly increase the temperature inside the server. To avoid such a problem, Nidec proposes redundancy where multiple fans are placed in parallel to secure the server’s performance until the replacement is over.

As big data, 5G, and other technological innovations become common, the competition among companies for better server performance and sizes intensifies. Where products are developed, the maximum level of improvement is required, and fans cannot be those for general purposes. There, products are underdevelopment jointly with Nidec’s engineers. Being excellent at offering high-value-added products based on customers’ specifications, we will continue to hone our ability to identify the needs of our customers and offer them products.