July 22, 2022

- Standard machines to meet the diverse needs for machining large components

To improve customers’ productivity based on the concept, “excellent machining, fast, and easy to operate”

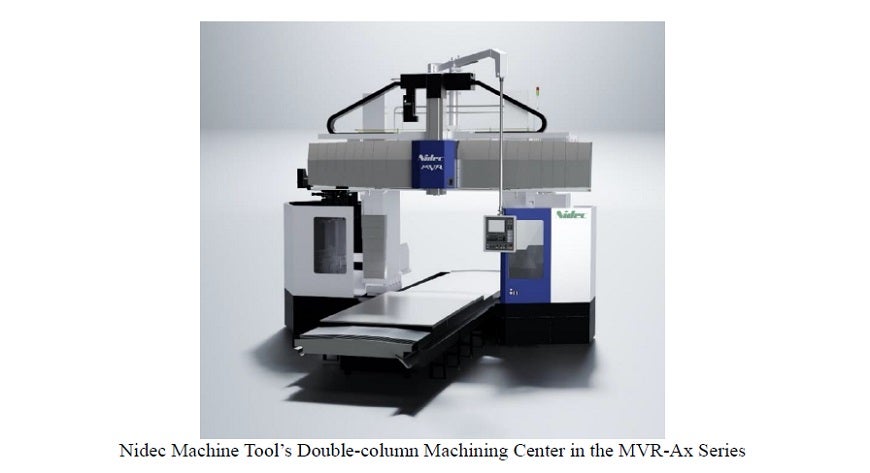

Nidec Machine Tool Corporation (Kenichi Wakabayashi, President, headquartered in Ritto, Shiga Prefecture) announced today that it has launched MVR-Ax, the series of the company’s new models of double-column machining centers. These new products were developed as easy-to-use machines to meet the diverse needs of factories that machine large-size components. Together with current series, i.e., high-end model MVR-Hx and standard model MVR-Cx both launched last October, the MVR-Ax series can apply many optional functions – ranging from a table size that can accommodate large-size workpieces to an abundance of attachments to the main axis to automated functions such as an automatic palette changer – for a variety of users’ applications. In addition, the highperformance machining technology and the digital technology to improve operability and maintenance capability enhance the MVR-Ax machining centers’ overall productivity. We will offer these new machines to our products’ users, domestic and overseas, to develop new markets.

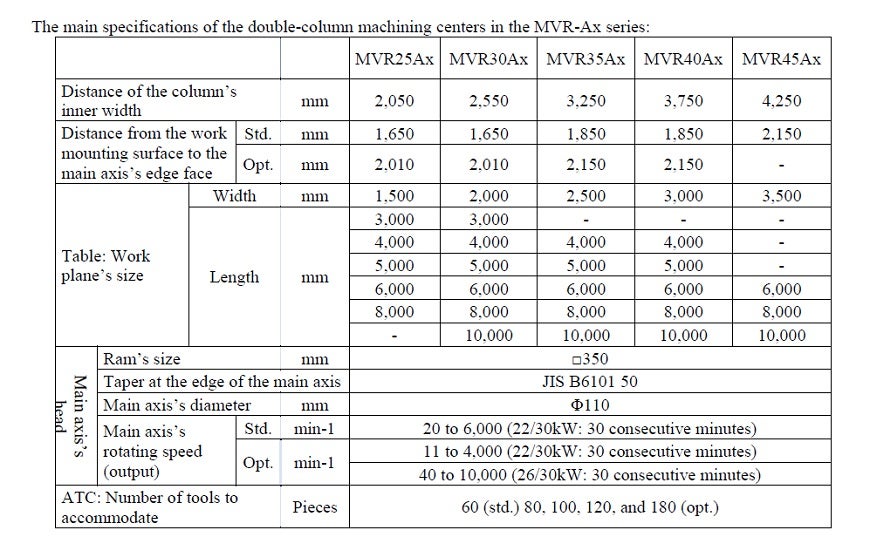

The MVR-Ax series are equipped with a main axis that rotates at a standard speed of 6,000 rpm to machine largesize workpieces such as industrial, construction, semiconductor manufacturing, and power-generating equipments, and with a gear drive main axis (opt.) (4,000rpm, with a maximum torque of 3,430N▪m) for heavy duty cutting operations. Combined with rigid structures of the main unit, which remain stable with this high torque, the products have sturdy ram main axes that enhance the cutting capability during ram movement, while enhancing the performance of the machining of tall components’ lateral sides. Additionally, a large number of attachments enable MVR-Ax series to machine objects of various shapes, including narrow sections, multifaceted surfaces, slant planes, and adjustable surfaces. Furthermore, the individual axes’ rapid feeds are top-class in the industry, with 30m/min. for the x-axis, 32m/min. for the y-axis, 20m/min. for the z-axis, and 5m/min. for the w-axis. The shortened noncutting time makes the MVR-Ax series highly productive.

To seek usability, we reflected the voices of our products’ users in the MVR-Ax series by installing, as standards, the “NidecNavi,” an operational assistance function to help the operator make NC programs and perform centering work efficiently, and the “simple collision prevention function” to prevent tool-work collision. In addition, with the use of “DIASCOPE,” our company’s unique IoT platform, we provide swift, secure, and hassle-free support for the MVR-Ax series users. The products’ other features include, among technologies to enhance their environmental performance, an idling stop function for the oil cooler and the hydraulic unit to reduce electricity consumption and serve other energy-conserving purposes.

Having been delivered to and widely used in mold, industrial machinery, construction equipment, semiconductor manufacturing equipments and many other fields of business, the MVR series seeks to achieve an optimum mechanical performance, as well as an excellent usability and environmental performance based on its user-friendly, secure, and supportive designs.

Nidec Machine Tool stays committed to offering machine tools that are needed in all industries to contribute to improving our customers’ manufacturing capabilities.

|

For inquiries on this new product, please contact Nidec Machine Tool Corporation’s Sales Division ¥at +81-077-552-9760. |

Cautionary Statement Concerning Forward-Looking Information

This press release contains forward-looking statements regarding the intent, belief, strategy, plans or expectations of the Nidec Group or other parties. Such forward-looking statements are not guarantees of future performance or events and involve risks and uncertainties. Actual results may differ materially from those described in such forwardlooking statements as a result of various factors, including, but not limited to, the risks to successfully integrating the acquired business with the Nidec Group, the anticipated benefits of the Transaction not being realized, changes in general economic conditions, shifts in technology or user preferences for particular technologies and changes in business and regulatory environments. The Nidec Group does not undertake any obligation to update the forward-looking statements contained herein or the reasons why actual results could differ from those projected in the forward-looking statements except as may be required by law.