CSR

E / Environment

ESG stands for Environmental Social and Governance. It is a general term used to measure the sustainability and ethical, environmental impact of businesses on society. Socially responsible investors make investment decisions using ESG criteria. This section discusses our key approaches to managing its "E" aspects.

Nidec Mobility Group Environmental Policy

We realize that the perpetual protection of the global environment is an important issue common to all mankind, and aim to minimize environmental load through environmentally friendly business activities to carry out our social responsibilities.

- 1. In order to reduce environmental load, we will place a strong focus on environment in our business activities, that is design and development of automotive electric devices and related components.

- 2. We will reduce greenhouse gas emissions throughout the value chain to prevent global warming.

- 3. We will make efficient use of environmental resources in the entire product lifecycle (product design, process/machine design, procurement, production, transportation, use, and disposal).

- 4. We will work to prevent pollution, such as water, air, and soil pollution, and prevent contamination.

- 5. We will fully understand risks caused by legal violations and perform organization-wide activities for violation prevention to ensure compliance with applicable environmental regulations and other agreed-upon requirements.

- 6. To improve environmental performance, we will continue in the establishment of our corporate environmental system by making continualimprovements and holding ourselves accountable by ensuring disclosure of environmental information to our stakeholders.

Revised on November 1, 2019

President & CEO

Medium-term Environmental Conservation Plan

Nidec Group has set goals in four areas: 1) reducing the environmental impact of our business, 2) contributing to the environment through our products, 3) environmental management activities, and 4) protecting the natural environment, and is working to achieve these goals.

Please refer to here for more details

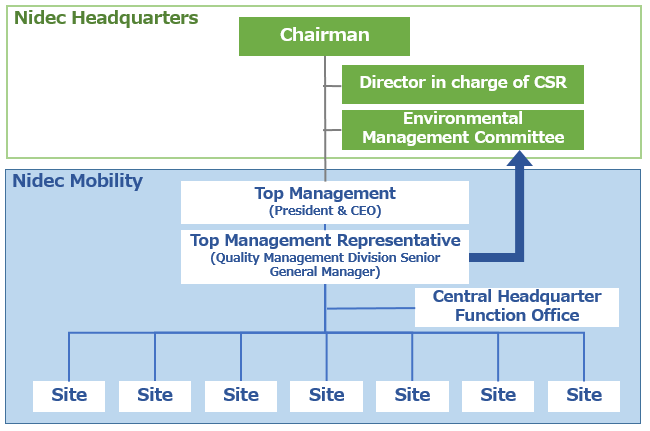

Environmental Promotion System

With our governing body at our headquarters, we have acquired ISO14001 certification for multiple global sites.

Under the umbrella of our environmental governing body,

seven sites in Japan and around the world are promoting environmental activities. Specifically,

we have established environmental representatives at each site.

These representatives are responsible for promoting environmental improvement activities and maintaining our systems

for environmental management at each site, and for working in collaboration vertically and horizontally among the sites

while we continue to strengthen governance by operating these sites under a unified policy and common environmental manual.

In addition, by horizontally deploying improvement examples and know-how to other sites,

we create synergistic efforts as a group and improve the group’s performance.

The environmental management officer of the governing body belongs to the “EM (Environmental Management) Committee” of the Nidec Headquarters,

and is working in accordance with the Nidec Group’s environmental activity policy.

Environmental Management System

Please refer to here for the current ISO 14001 certification status.

In addition to reducing the environmental load generated at our company,

we are also working to reduce the environmental impact at the consumer end-use stage

in the life cycle of the products that we design, develop, and produce.

The majority of CO2 emissions in the life cycle of fossil fuel-based vehicles are accounted for while the vehicle is driven.

By improving vehicle fuel efficiency and providing parts for environmentally friendly vehicle such as EVs,

we are contributing to the prevention of global warming and helping to reduce CO2 emission generated from vehicle use.

We have established an internal system to register and track products designed and developed in-house

that contribute directly or indirectly to environmental conservation.

Our formula for calculating the total amount of environmental contribution is based on the contribution per product unit,

and the number of units shipped.

| Category | Definition |

|---|---|

| Direct Effect | The size and weight of new products compared to the size and weight of existing products manufactured by us or other companies and the resulting improvement in fuel economy and reduced CO2 emissions. |

| Indirect Effect | The effect of reduced CO2 emissions resulting from the incorporation of our products into key components of our customers' energy-saving products (automobiles and motorcycles). |

* Please refer to here for specific environmentally friendly products.

Actions to Achieve Carbon Neutrality

We are participating in Nidec group's efforts toward carbon neutrality. Nidec group has set a new mid-term strategic goal, "Vision 2025," and has set "achieving carbon neutrality by fiscal 2040" as a pillar of its efforts.

Please refer to here for more ditails.

Reduction of Greenhouse Gas Emissions:

Promoting the Use of Renewable Energy

We are promoting the use of electricity derived from natural energy that does not emit CO2.

The Group's site in Brazil purchases only electricity from hydroelectric power generation

and uses 100% renewable energy. Our sites in Japan and China have implemented in-house solar power generation facilities

to make some of the electricity as green energy. As of fiscal 2021,

the Group's renewable energy implementation rate was approximately 6.3%.

Currently, we are considering switching purchased electricity to electricity with a low CO2 emission factor

and implementing renewable energy using the PPA(*) model, and are working to actively use energy friendly to the global environment.

* PPA(Power Purchase Agreement):

Business operators can rent rooftops of facilities and idle land owned by companies and local governments,

install renewable energy power generation facilities free of charge,

so corporations and municipalities can use the generated electricity at their facilities,

thereby reducing electricity charges and CO2 emissions.

Reduction of Greenhouse Gas Emissions:

Examples of Energy Conservation

We are actively engaged in energy-saving activities on a global basis according to our medium-term plan to reduce greenhouse gas emissions. In order to enhance energy-saving results at each global site, we conduct energy-saving diagnosis and guidance by experts within the Environmental Management Department, develop energy-saving human resources, and horizontally deploy successful cases within the Group. The table below introduces examples of energy-saving measures implemented.

| Category | Energy-Saving Measures | Details |

|---|---|---|

| Air cooling | Maximum use of free cooling (suspension of centrifugal chiller operation) | When producing chilled water used in air conditioning equipment, we switch from centrifugal chillers, which consume a lot of electricity, to free cooling, which consumes less power, in the winter when the outside temperature drops, reducing power consumption by 55% per year. Also, during the intermediate season other than winter, we frequently check the outside temperature and switch the operation when the outside temperature drops below 7°C to utilize free cooling. |

| Micromanagement of air conditioner operation on holidays | Every week, we check the weekend production plan in advance and run the air conditioner to a minimum according to the plan. | |

| Reduction of air conditioning power consumption by measures to exhaust heat from production facilities. | For equipment that has exhaust heat, such as reflow ovens and solder bathes, heat is exhausted to the outside of the room with ducts and heat insulating material is attached to the top plate of the equipment to suppress the indoor temperature rise and reduce the power consumption of air conditioning. | |

| Lighting | Switching to LED lighting |

At our five production sites and head office, all fluorescent tubes have been converted to LEDs.

92% of the total has been completed, and the rest are working toward LED conversion. Overall, 92% has been completed by this and we are working the rest toward LED conversion. |

| Reduction of the number of lights | We have reduced the number of lights used in compliance with laws and regulations for each location and operation. | |

| Compressor | Managing compressor air leaks | We regularly check for compressor air leaks and repair them. We also take preventive measures such as replacement with parts that are less prone to air leakage. |

| Power consumption reduction by reducing the pressure of the air supplied to the manufacturing process | We investigated the air pressure required by all production facilities and set a target value for the pressure to be supplied. Air boosters are installed in equipment with higher pressure requirements than the target values to meet specifications. As a result, the overall supply pressure was reduced. | |

| Production equipment | Reduction of power consumption through thermal insulation measures for production equipment | Heat insulation is attached to the top plate of the heat-source equipment to prevent heat from escaping and reduce the electric power for heating. |

Waste Management

Water Management

In order to effectively utilize water, which is a limited resource, and conduct environmentally friendly business activities,

we are working to reduce water consumption (reduce) and circulate (reuse and recycle) water consumption through improvements

in manufacturing processes and equipment operations.

As an example of water conservation,

our China site has installed equipment that can capture and reuse the drainage water from air conditioning and humidification systems.

As a result, we were able to reduce our water consumption by 7,800 tons per year at this location.

Chemical Substance Management:

Initiatives for the Total Abolition of Fluorocarbons

We are working toward the total abolition of fluorocarbon-target substances (generally employed as refrigerants), which are the main cause of ozone depletion. We are systematically switching to alternative fluorocarbon and fluorocarbon-free equipment that do not contain these substances.

Chemical Substance Management:

Activities to reduce VOCs Consumption and Emissions to the Atmosphere

We are working to reduce the amount of VOCs(Volatile Organic Compounds) used and emission to prevent air pollution.

Until now, we were using coating materials containing toluene* in our products. In order to reduce the amount of VOCs used,

we now promote the use of coatings or toluene-free coatings from the product design stage. Furthermore,

in order to control the emission of VOCs into the atmosphere, we installed a system to adsorb VOCs with activated carbon before emitting them.

* Toluene is one of the VOCs.

Biodiversity Conservation Initiatives

In addition, in order to protect the rich natural ecosystems that are close to our working environment, we are working directly to conserve biodiversity by introducing facilities and equipment that take impacts on biodiversity into consideration.

Activity Album

| Base | Activity |

|---|---|

| Japan | Balancing insect control and insect protection |

| Japan | Gifu Butterfly (Luehdorfia japonica) Conservation |