Precision Cutting Tools|Precision Cutting Tools|Hobs

Hobs

The handling companies : Nidec Machine Tool Corporation

- Contact information for product inquiry

- Contact us

SuperDry III Hob

Beyond the limit of high speed processing… "SuperDry III" Coating hob

High-speed hobbing at a cutting speed of 250 m/min. or more reduces the cycle time, extends tool life and achieves precision processing.

Features

- The coating strength, boding power and adhesion with base material are increased thanks to the improved coating structure.

- Improvement in coating structure raises coating strength and bonding power by increasing adhesion with the base material.

Samples

| Work | Module 2.25 |

|---|---|

| Pressure angle | 17.5° |

| Number of teeth | 52 |

| Helix angle | 23°LH |

| Material | 18CrMo4(HB180) |

| Hob | Outer diameter 75 mm, Material MACH7 |

| Number of start | 3 starts |

| Number of gash | 14 |

| with cutting face coating | |

| Cutting condition | Cutting speed 250m/min |

| Axial feed | 2.4mm/rev |

| Coaxial winding climb, no shift | |

Comparison graph of tool wears

Picture illustrating wear after hobbing 80 units of work pieces

SuperDry III

SuperDry II

Tooth profile chart X 500 X 4

Lead chart X 500 X 2

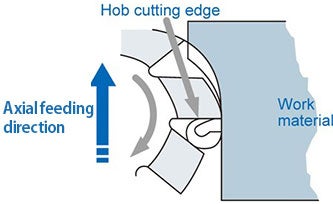

Processing by hobbing

Mount a hob on the hobbing machine, position the hob and the work piece in rack and pinion order, perform synchronous rotation, and feed the hob to work piece’s gear width direction; this enables highly efficient and accurate gear processing.

Hob identifies itself either as numerous number of teeth or as a single tooth.

One tooth of a work piece is generated per one rotation.

Feeds the hob to a work piece' s gear width direction

Efficiency in processing may improve if the number of starts for the hob is increases but the number of blade will decrease and polygonal error may be formed at the same time.

Machine must have sufficient rigidity and strength.

Gear cutting method in hobbing

Conventional hobbing

Hob rotates from the top face to the bottom face of a work piece.

Climb hobbing

Hob rotates from the bottom face to the top face of a work piece.

Precaution for sharpening

Hob needs grinding as cutting edge surface may become worn; this process is called "Resharpening". Improper resharpening may affect the precision of the hob. Following indicates the typical example of errors in the cutter form:

Δγδ=hobbing lateral face lip clearance (tanΔγδ=tanε・tanαn・cosγ)

ε=external lip clearance

αn=tooth pressure angle

γ=hobbing feeding angle

rρ=hobbing pitch circle diameter

Influence from cutting load fluctuation

Hob setting angle error and tooth thickness

Number of starts and polygonal error