Laser・Semiconductore manufacturing equipment・Metal additive manufacturing|Laser processing system|Laser micro machining machines

Laser micro machining system ABLASER

The handling companies : Nidec Machine Tool Corporation

- Contact information for product inquiry

- Contact us

The original laser head technologies are for high precision and high efficiency.

Features

The optical laser head on the original technologies enables high precision helical machining.

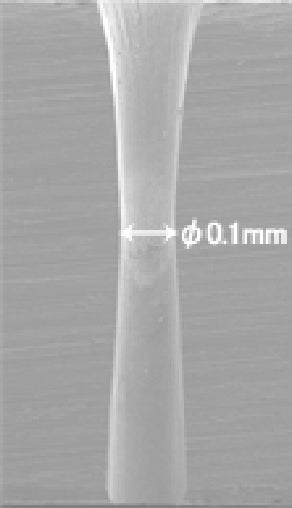

The laser head adopts a prism rotator that adjusts and rotates the laser beam to an arbitrary hole diameter, enabling shape processing with sharp edges. It is also possible to drill holes of any cross-sectional shape, such as straight, tapered, reverse tapered or hand-drum-shaped.

Schematic diagram of helical processing

-

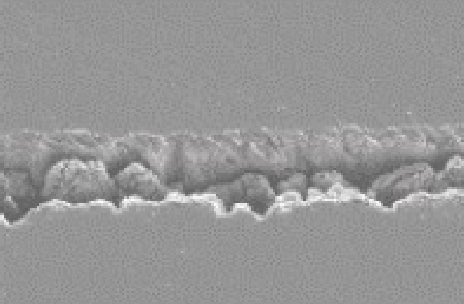

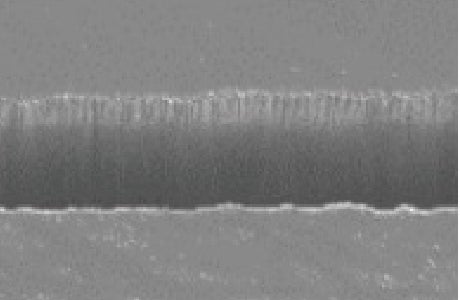

Normal non-helical processing -

Our helical milling processing

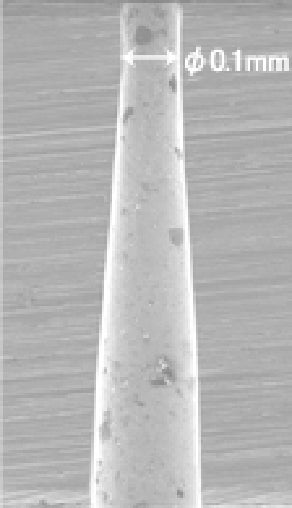

Cutting test results for silicon material

-

Straight hole -

Reverse taper hole -

Hand-drum hole

Processing example

Silicon surface straight microhole drilling

| Material | Silicon wafer |

|---|---|

| Hole diameter | 0.15 mm |

| Plate thickness | 0.5 mm |

| Processing time | 9.0 sec/hole |

SiC surface straight microhole drilling

| Material | SiC |

|---|---|

| Hole diameter | 0.08 mm |

| Plate thickness | 1.0 mm |

| Processing time | 15.0 sec/hole |

Machinable ceramic surface straight microhole drilling

| Material | Machinable ceramic |

|---|---|

| Hole diameter | 0.06 mm |

| Plate thickness | 0.6 mm |

| Processing time | 5.0 sec/hole |

Helical milling hole drilling

| Material | Platinum |

|---|---|

| Hole diameter | ⌀2.0 mm |

| Plate thickness | 1.5 mm |

| Processing time | 4.0 sec/hole |

Lithium tantalate (LiTaO3)

| Hole diameter | 0.02 mm |

|---|---|

| Pitch | 0.07 mm |

| Plate thickness | 0.25 mm |

| Aspect ratio | 12.5 |

It is possible to drill ⌀0.02 mm holes in lithium tantalate,

which is used in semiconductor products.

Lithium tantalate & silicon wafer

| Hole diameter | 0.015 mm |

|---|---|

| Pitch | 0.1 mm |

| Plate thickness | 0.2 mm |

| Aspect ratio | 13.3 |

Even for multi-layered materials such as lithium tantalate and silicon, which are used in semiconductor products, holes of ⌀0.015 mm can be drilled using simultaneous processing.

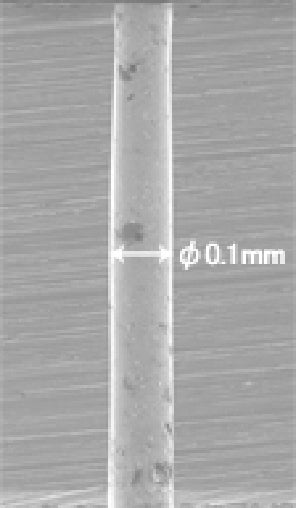

Stainless steel Small diameter hole drilling

| Hole diameter | 0.027 mm |

|---|---|

| Plate thickness | 0.30 mm |

| Aspect ratio | 11.1 |

With the green laser ABLASER, it is possible to drill holes with a minimum diameter of ⌀27 μm.

Cemented carbide Square hole drilling

| Size | 0.20 mm |

|---|---|

| Plate thickness | 1.00 mm |

Even with 1.0 mm thick cemented carbide, square holes with clean edges can be drilled.

Quartz glass Hole drilling

| Hole diameter | φ0.185 mm |

|---|---|

| Pitch | 0.300 mm |

| Plate thickness | 0.2 mm |

| Aspect ratio | 1.08 |

It is possible to process quartz glass with good roundness without thermal effects.

Specifications

| Item | Specifications | Remarks |

|---|---|---|

| X-axis (mm) | 300 | Precision scale equipped as standard |

| Y-axis (mm) | 200 | Precision scale equipped as standard |

| Z-axis (mm) | 100 | Precision scale equipped as standard |

| Positioning accuracy (mm) | ±0.002 | |

| Maximum feed rate (m/min) | 10 | |

| NC device | FANUC 31iB | |

| Maximum output | 30W | |

| Wavelength (nm) | 515 | |

| Laser head | Own products | |

| Workpiece diameter (mm) | ⌀0.05 to 0.3 | It may vary depending on the material. |

| Taper hole control | Forward taper/reverse taper/hand-drum shaped | |

| Assist gas | Selectable for each workpiece | |

| Width × depth × height | 2,040 × 2,590 × 2,220 | Machine body only. Excludes control enclosure and attachments. |

| Weight | 5.0 t | Machine body only. Excludes control enclosure and attachments. |

| Fume collector | Attachments | |

| Internal air conditioning | ||

| X/Y/Z axis bellows | Heat resistant specifications | |

| Option | Centering function Supports sorters Supports clean rooms Other requests are available. |