Machine Tools|Large Machines|Double column type Milling Machines

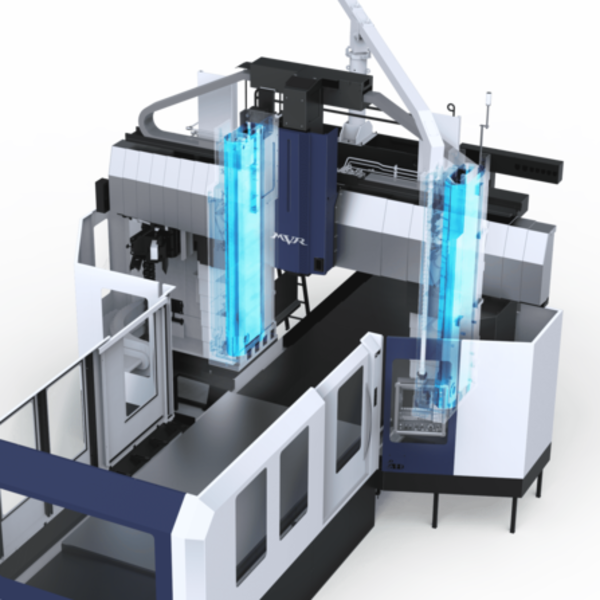

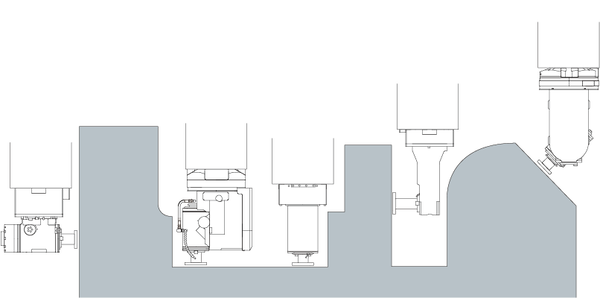

Double-Column, 5-Face Milling Machine MVR-Hx series

The companies handling the product:Nidec Machine Tool Corporation

- Contact information for product inquiry

- Contact us

Do more with Five-face Milling. Added freedom for machining.

MVR25Hx

- Distance between columns (mm)

- 2,050

- Distance from table top to spindle nose (mm)

- std. 1,650

opt. 2,010

MVR30Hx

- Distance between columns (mm)

- 2,550

- Distance from table top to spindle nose (mm)

- std. 1,650

opt. 2,010

MVR35Hx

- Distance between columns (mm)

- 3,250

- Distance from table top to spindle nose (mm)

- std. 1,850

opt. 2,150

MVR40Hx

- Distance between columns (mm)

- 3,750

- Distance from table top to spindle nose (mm)

- std. 1,850

opt. 2,150

MVR45Hx

- Distance between columns (mm)

- 4,250

- Distance from table top to spindle nose (mm)

- std. 2,150

2022 Nikkan Kogyo Shimbun 52nd Machine Industry Design Award IDEA Award Japan Machine Tool Builders' Association Award

Features

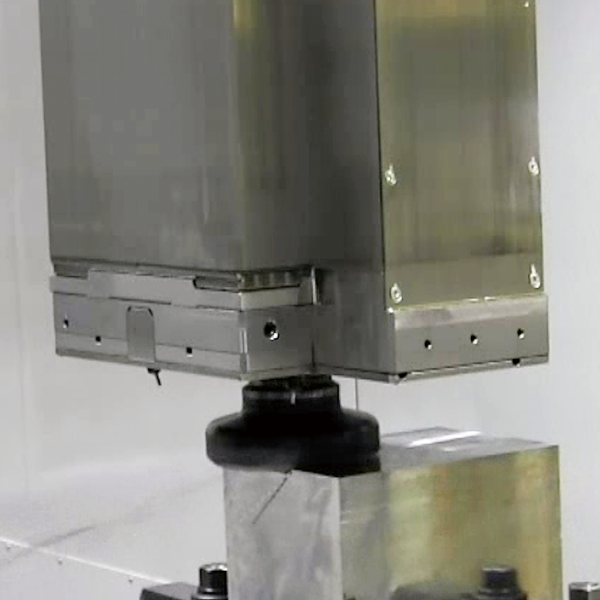

Outstanding accuracy

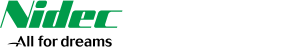

The spindle core cooling that suppresses thermal displacement

- It reduces steps and bites on the machined surface.

- High-precision machining is possible at the speed range from low to high.

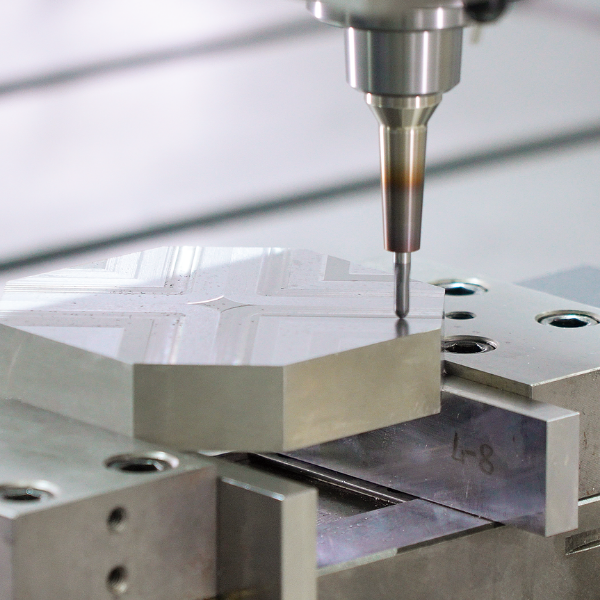

The sample surface is divided into areas and processed with 5 tools.

Rotation speed to 4,000 to 8,000 min-1 for each tool, the step at the area boundary is 3.5 μm at the maximum.

Thermo-stabilizer column maintains geometric accuracy without being affected by changes in environmental temperature

- Setup is possible without worrying about temperature changes over time

- The origin does not go out of order even during long-time machining, reducing the frequency of centering.

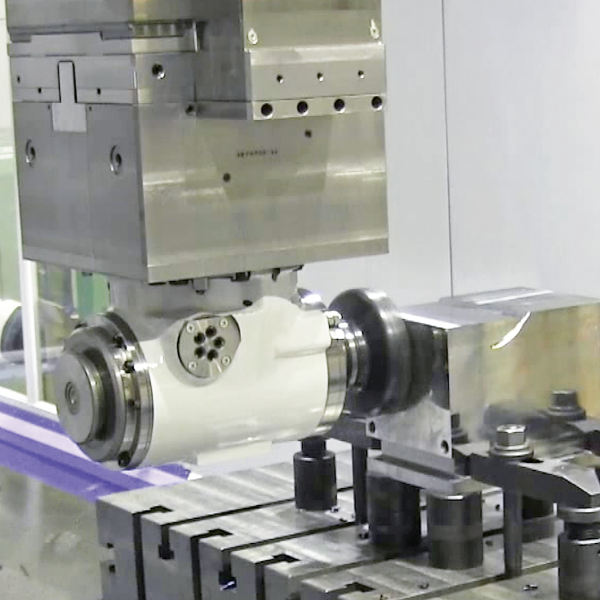

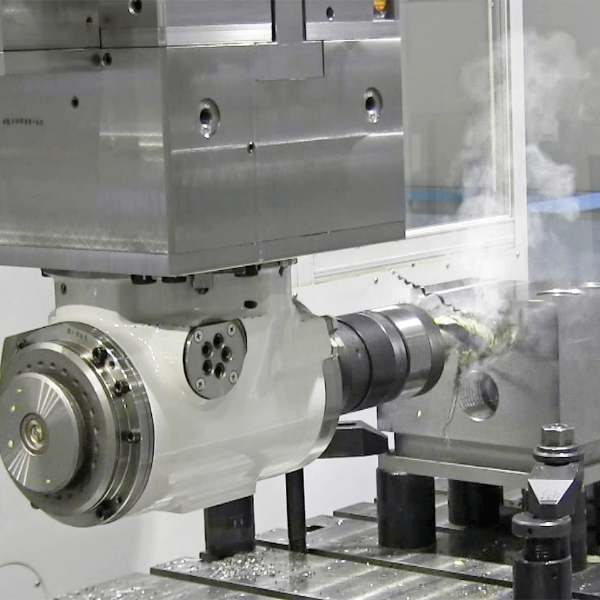

Prominent cutting ability

Powerful heavy cutting on both vertical and horizontal axes

(Vertical spindle)

(Right angle head)

(Vertical spindle)

4,000min-1

(Right angle head)

Versatile performance

Many kinds of attachments and package options available

You can select the attachment according to the shape of part of workpieces such as narrow part, inclined surface, free curved surface, or to the machining method like high-speed machining, high-precision machining etc.

Example of attachment according to part shapes

| Right angle head | Powerful Right angle head High Right angle head Small Right angle head |

|---|---|

| Extension head | Extension head (long) Extension head (short) Extension head (small diameter) High speed Extension head High speed Extension head (built-in motor) |

| Universal head | Universal head (offset type) Universal head (center head) High speed universal head |

| 5-axis machining head | 5-axis (NC2-axis) attachment |

"Operability" that expands the possibilities

- 15 inch large screen, touch screen operation panel

- Equipped with the latest NC FANUC 31i-MODEL B Plus

- "Tool magazine operation panel" with touch panel allows you to call pot numbers and edit tool data

"Tool magazine operation panel" is placed near the magazine

Specifications

| Item / Model | MVR28/34Dχ | MVR33/39Dχ | MVR38/44Dχ | MVR43/49Dχ | ||

|---|---|---|---|---|---|---|

| Table | Working area | Width (mm) | 2,000 | 2,500 | 3,000 | 3,500 |

| Length (mm) | 4,000 (opt. 5,000, 6,000, 8,000) | 5,000 (opt. 6,000, 8,000) | ||||

| Loading capacity (ton/m) | 25/4.0 (opt. 30/5.0, 36/6.0, 48/8.0) | 35/5.0 (opt. 42/6.0, 56/8.0) | ||||

| Throat clearance between columns (mm) | 2,850 | 3,350 | 3,850 | 4,350 | ||

| Distance from spindle end to table surface (mm) | 2,050 | 3,050 | 3,050 | |||

| (opt. 2,550, 3,050) | (opt. 2,050, 2,550) | (opt. 3,550, 4,050) | ||||

| (opt. 3,550, 4,050) | (opt. 3,550, 4,050) | - | ||||

| Ram | Ram size (mm) | □400 | ||||

| Spindle speed (min-1) | 7 to 4,000 | |||||

| Spindle motor output (continuous/30 min) (kW) | 37/45 (opt. 45/55) | |||||

| ATC tool storage capacity (pcs) | 60 | |||||

| (opt. 80, 100, 120, 160, 200, 240) | ||||||

| Machine weight (kg/working area mm) | 107,000/4,000 | 110,000/4,000 | 118,000/5,000 | 121,000/5,000 | ||