MX-1 SHAPER CUTTER

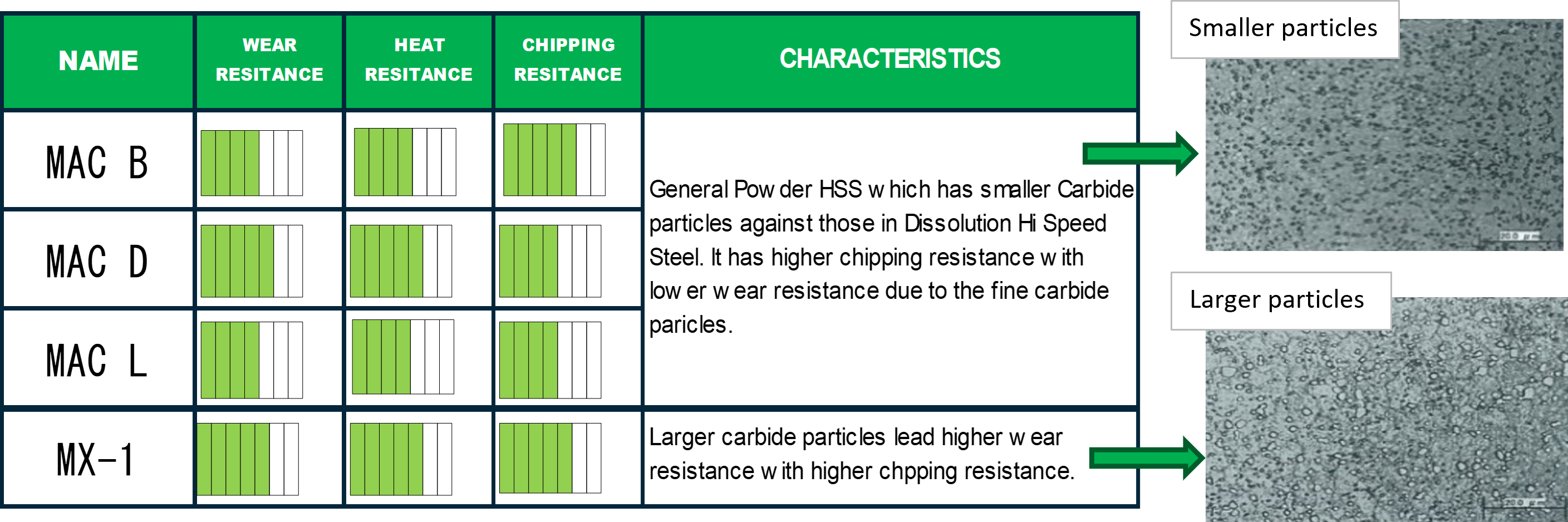

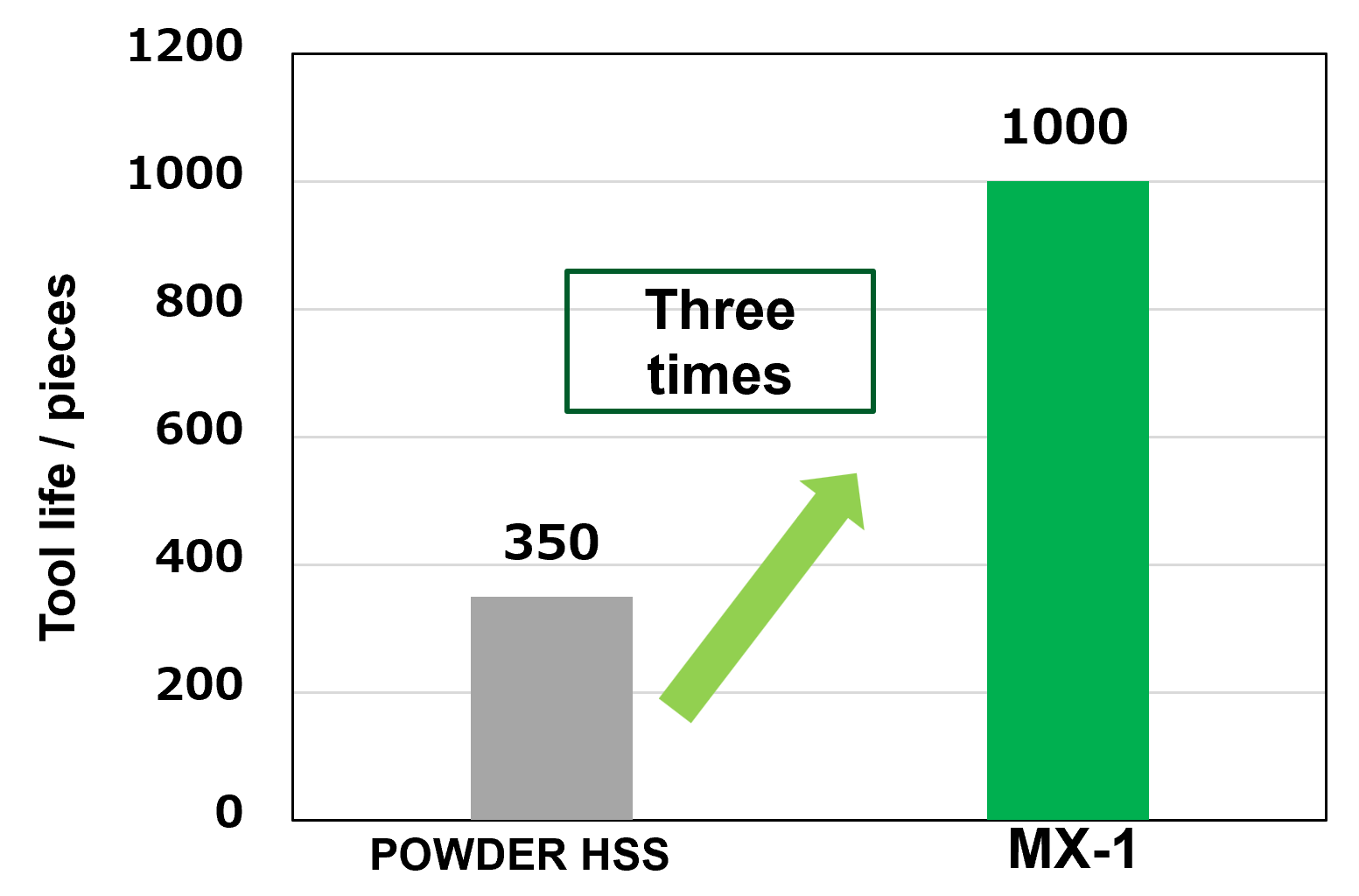

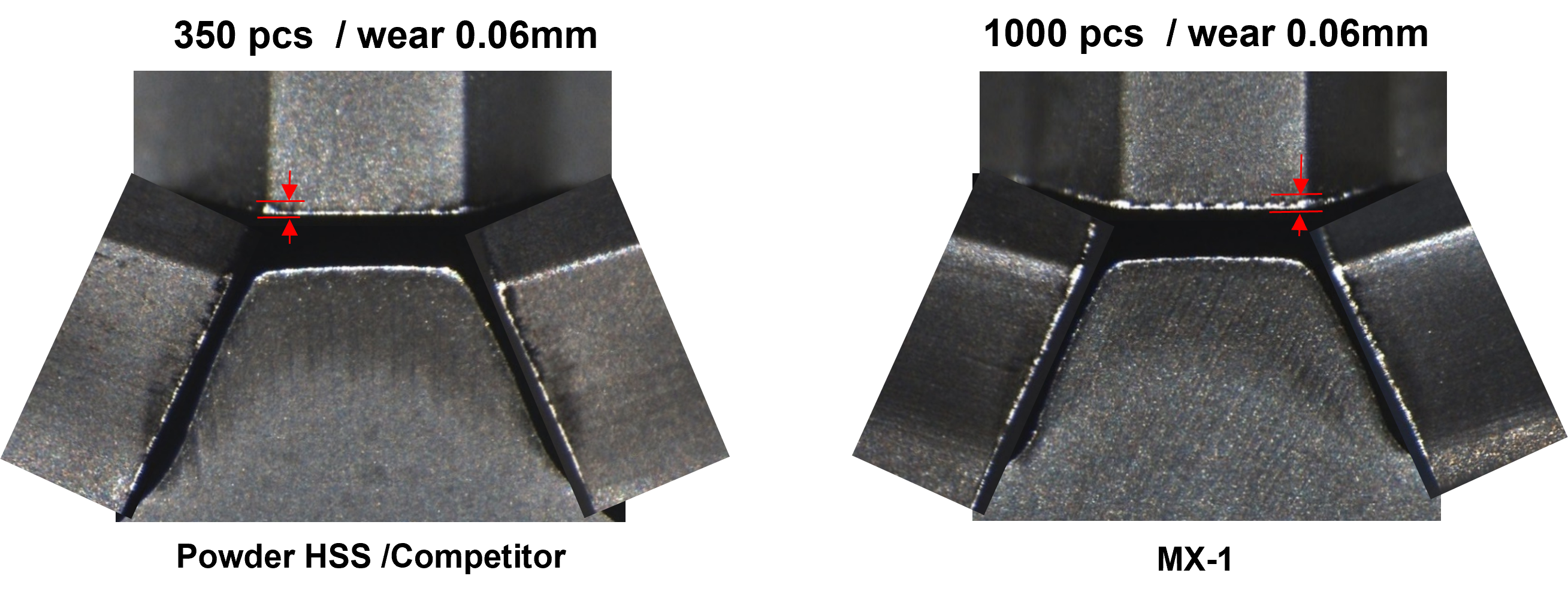

Hybrid composition ,chipping resistance as Powder HSS and wear resistance as Dissolution HSS are altogether.

HSS = High Speed Steel.

Applications

| Work piece | Module 1.3 PA30° SPUR NT30 Carburized steel |

|---|---|

| Cutter | Outer dia. 30mm NT20 MX-1 with SuperDry PVD COAT |

| Cutting Conditions | Strokes 850/920 str/min Circumference feed 1.5/0.50 mm/str Radius feed 0.020/0.012 mm/str |

Products page

- DESCRIPTION OF GEAR INSPECTION SHEET PARAMETERS

- Instruction of measuring between pin diameter cut with broaches

- Design tips for hobbing cutter starts and flutes

- Selection Map / Tool materials, Surface treatments

- Brand-new raw material exclusively desined for Broaching tools

- Influence on hob tool life against heat treatment of pre-hobbing materials

- Influence on tooth thickness and tip chamfer caused by adjusting hob set angle in order to eliminate scratch mark on the flank

- A material that takes durability to new frontiers GRANMET SF(Speed Fine)

- High speed shaping cut - Large circumference feed -

- Effective hob shift length

- New Coating MightyShield Σ

- Dry hobbing / countermeasure for scratch

- Inspection method of resharpening accuracy for hobs - Indexing of gashes

- MX-1 HOB

- Inspection method of resharpening accuracy for hobs - Top rake of cutting face

- MACH13 HOB

- Troubleshooting for gear shaving

- Trouble shooting for internal broaching 【 Eccentricity of broaching hole against pre broaching hole】

- Brand-new raw material exclusively desined for Skiving cutters GRANMET SK

- Ultimate coating exclusively desined for Shaving cutters - MightyShield ε -

- MACH11 HOB

- Exquisite coating exclusively designed for Super-fine pitch cutters/Super-fine pitch gear cutter

- BROACH TOOL / Types and Applications

- MX-1 SHAPER CUTTER

- SHAPER CUTTER / How to examine the helical guide common use