MACH13 HOB

This dissolution HSS boosts performance of resistance for the chipping

Characteristics

- 1.The fine particle with uniform placement enhances the chipping resistance.

- 2.Strengthening of substrate with salt heat treatment performs the resistance against chipping and wear.

- 3.It enhances the cutting face smooth due to the sharp cutting edge of the tool.

Chipping resitance

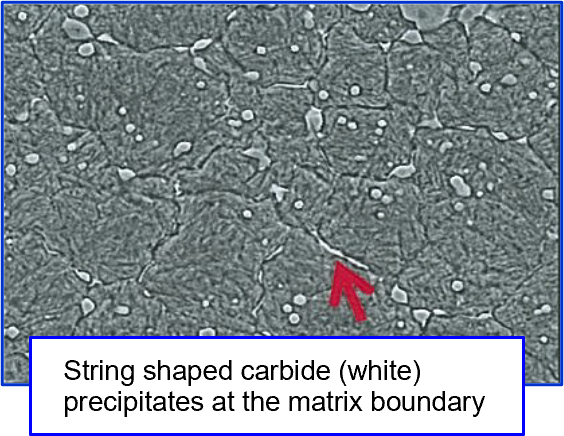

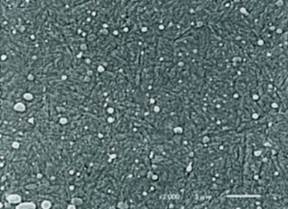

| Structure after general heat treatment | Structure after MACH13 heat treatment |

|---|---|

|  |

| Carbides precipitation at the boundary of matrix. It is easy to chip because the bond between particles is weak, also Abrasion resistance is reduced because carbides do not dissolve in the matrix. | No carbides precipitation at matrix boundaries. The strong bond between the matrix makes it difficult to chip, and the carbides dissolve in the matrix to improve wear resistance. |

Cut surface roughness

- 【Workpiece dimensions】

- Module 3

- NT 18

- PA 18°

- HA 30°

- 【Cutting condition 】

- V=150m/min

- f=1.0mm/rev

- Climb cut,DRY

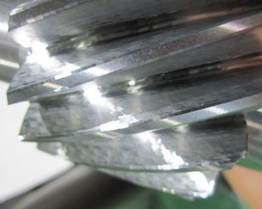

Cut result

【Workpiece Dimensions】

- M 2.25

- PA 17.5°

- NT 46 HA 23°

- Material SCM415

【Hob Dimensions】

- Starts3 RH Flutes16

- Material MACH7/MACH13

- PVD coat SuperDryIII

【Cutting Conditions】

- Cutting speed 300m/min

- Axial feed 2.4mm/rev

- Climb cut / DRY cut

- Cut length 60m (No shift)