Laser-Machines

Drilling holes in mechanical pencil lead

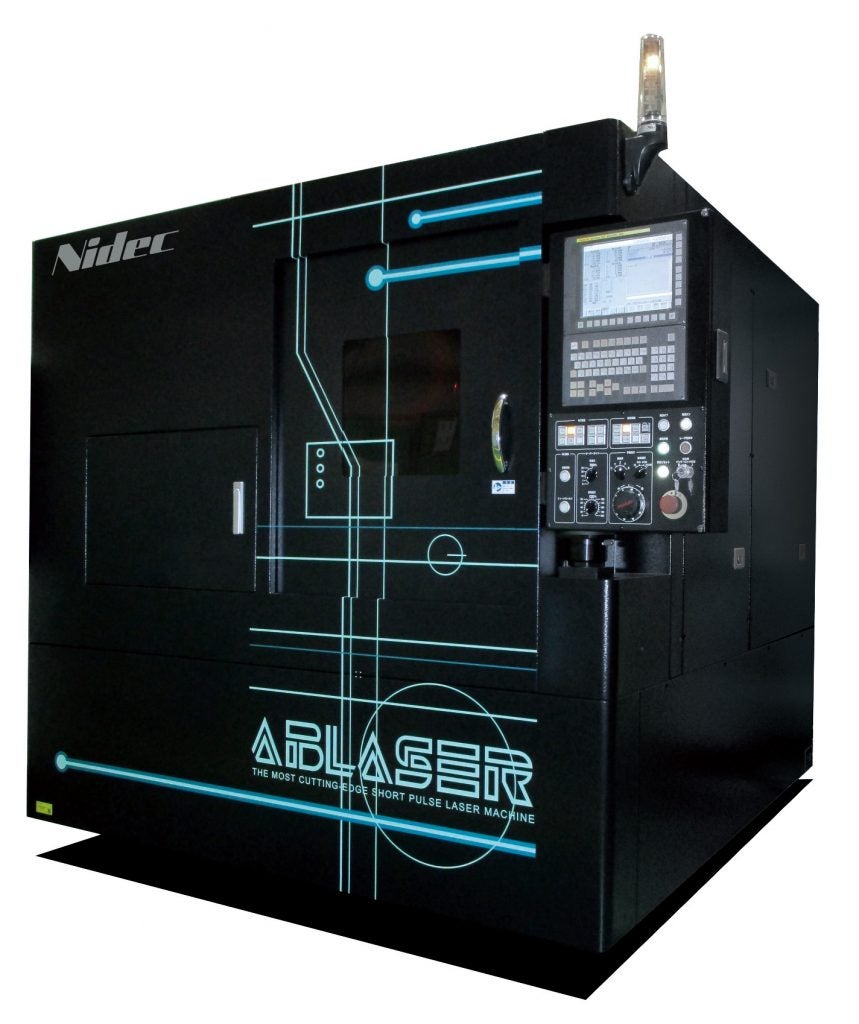

- With the combination of a short pulse duration green laser enabling minimal thermal effects on machining and the advanced precision positioning technology that Nidec Machine Tool have developed as a leading machine tool manufacturer, ABLASER achieves innovative micron-level precision machining.

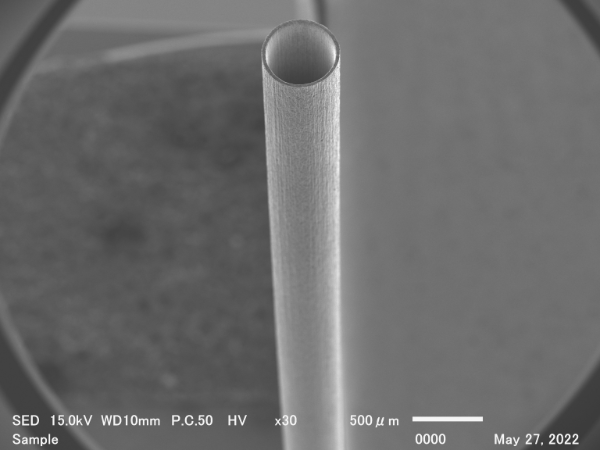

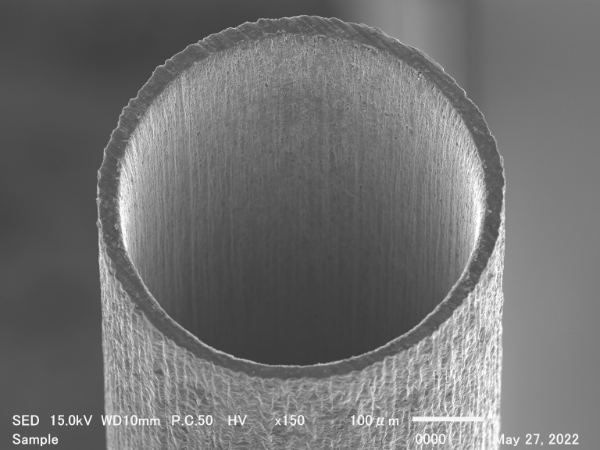

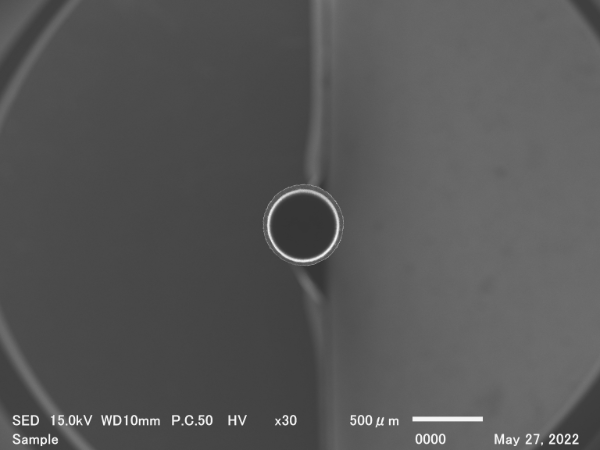

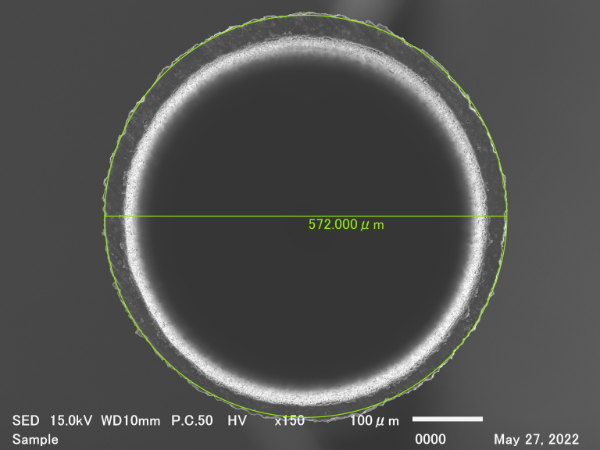

- In this case, we successfully drilled a hole with a depth of approximately 2mm in a φ0.5mm, HB hardness mechanical pencil lead. The processing was done without breaking the brittle pencil lead, while preserving thin sections.

Target workpiece

Trial services for micro-machining and for room temperature wafer bonding

We offer charged trial services for micro-machining and room temperature wafer bonding.

If your have some of following requests, please contact us.