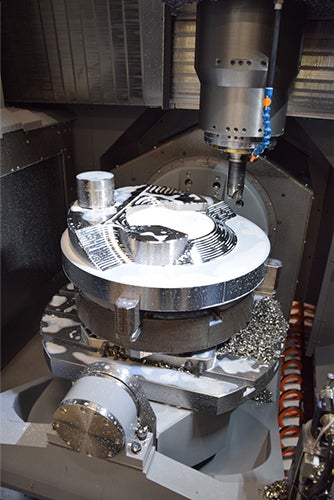

5 Axis Machining Center VB-X650

Kangasalan Kopal

Kangasalan Kopal was strengthened with a new five-axis – Demanding machining and tools

The subcontracted workshop Kangasalan Kopal continues on the path of development.

At the beginning of the year, the company's production expanded again with one new machine unit, when the five-axis VB-X650 machining center from the Japanese company Nidec OKK was installed in the workshop in the spring.

Kangasalan Kopal is a cheerful subcontracting company that has developed its production possibilities in recent years with purposeful steps and step by step. The company's operations were started in 2002 by Timo Korhonen, who has a long experience in project work and tool manufacturing. Tool design and project work were done in the beginning, but soon the company shifted its activities to machining after the next generation, Niko Korhonen, came to work.

"Niko started machining at us and the first production machine was other company's machining center. As the work quickly increased, a second one was soon bought, and later a third to share the workload. Now there are already six machining machines here, two of them five-axis machining centers. In addition, production is supported by a wire sparking machine. And we haven't given up on any of the machines we've bought here so far. All are in use", says Timo Korhonen.

Credit technology for precision work

Kangasalan Kopal traditionally invests in demanding 3D shapes and precision work. The company designs and manufactures e.g. tools, molds and fasteners. Customers are in many sectors of industry, which is one of the company's strengths. The sizes of the works vary from very small pieces of very sensitive optics to machine parts weighing several hundred kilograms. Sets are often small. "We have gradually tried to increase our serial sizes, and we have increased our capacity and machine base. The works are done in small and larger batches," says Niko Korhonen.

Today, Kopal's machinery is diverse and suitable for many jobs. The range has now expanded this year, when the company acquired a 5 Axis Machining Center VB-X650 model representing the newest offering of the Japanese Nidec OKK machining center from Mäkirintenie, which the manufacturer brought to the market as an extension of its offering last year. The machine increases the capacity of Kangasala Kopal in five-axis machining, which started in the house in 2019.

"Many jobs can be done with three axes, of course, but fewer handprints and thus accuracy are the advantage of five-axis technology. We are strengthening our opportunities." The new five-axis represents technology from a reliable manufacturer, the four-axis vertical spindle machining center VB-53 has been part of your company's stock for a long time. "VB-53 has served us well. We needed a machine, and when a suitable overall package could be polished, it was clear," says Timo Korhonen. "The demand for five-axis parts and components has been quite strong in recent years. The new machine will increase our capacity in this area alongside the previous heavily used machine," says Niko Korhonen.

Efficient machines, good tools

The VB-X650 supplied by Voss is a powerful package for five-axis work. In the VB-X series machine of the manufacturer that offers machines in several size classes, the X/Y/Z axis movements in the machine are 850/650/510 mm, the movement range of A is -110 – 110 degrees, C 360 degrees. A table with a diameter of 650 mm can carry a maximum of 350 kg. The spindle speed in the BT-40 conical machine is 15,000 1/min, the control is i Fanuc 31i-B5Plus. "Nidec OKK makes machines that are robust in structure and reliable in operation, and that fact was a strong factor in the balance sheet this time as well. In addition, the size category of the machine was suitable for us. We do the programming for the new machine as well with Mastercam," says Timo Korhonen.

Kangasalan Kopal continues closely on the path he has chosen. Demanding production remains at the heart of the work, when larger series are in the sights, the new technology also brings opportunities for that. "Efficient machines and good tools are the basic factors from which we will continue to seek competitiveness." Kangasalan Kopal now employs seven people in its operations. Kangasalan Kopal operates in premises that have been conveniently adapted to the expansion of operations over the years. They enable further investments. According to Timo Korhonen, one of their themes will be at least things related to measurement technology.

Kari Harju

Original release: Konekuriiri Magazine

INFO – In ENGLISH | KONEKURIIRI Finnish machine tools magazine

Kangasalan Kopal Oy

Established in 2002