NIDEC's Technical Capabilities

Brushless Motors

Brushless DC motors exhibit reduced energy use, long life, low noise, compact size and light weight characteristics.

Nidec is the world leader in the development and production of these high-performance motors.

Brush DC motors have various advantages such as high efficiency, potential to downsize, ability to run on electric power, and low manufacturing costs. However, these motors have a number of disadvantages such as noise due to brush friction, generation of sparks and electrical noise, and limited life due to brush wear. Development of the brushless DC motor has solved all these problems.

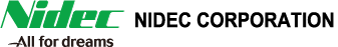

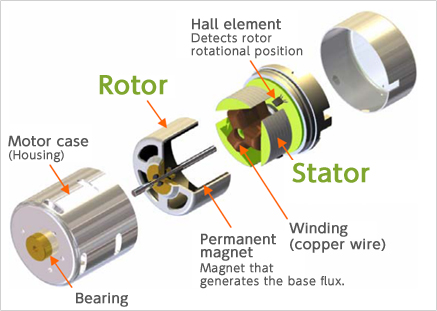

In the brushless DC motor, the rotor, made of a permanent magnet, is driven by the magnetic force of the stator's winding circuit. While the brush DC motor uses a brush and commutator for current switching, the brushless DC motor uses a sensor and an electronic circuit for current switching. Development of this motor has been made possible due to the evolution of the semiconductor and peripheral device technologies. This motor has advantageous characteristics of DC motors (current and voltage are respectively proportional to torque and rotating speed) and AC motors (brushless structure). Features of the brushless DC motor include compact size, high output, long life, and no generation of sparks and noise, and it is used in a wide range of applications from PCs to home appliances.

Characteristics and Classification of Brushless DC Motors

The brushless DC motor "rotates its magnet".

The rotor, made of a magnet, is rotated by magnetic fields that are generated by the current flowing through the stator windings. The current is switched by the sensor and electronic circuit.

Brushless DC motors have many advantages (in particular in the area of efficiency). When compared to other types of motor, the brushless DC motor has many advantages such as compact size, high output, low vibration, low noise, and long life.Outer rotor type (the rotor is outside the stator)

Inner rotor type (the rotor is inside the stator)

Motor Type Comparison Table

AC motor

Universal motor

Brush DC motors

Brushless DC motor

Stepping motor

Servo motor

Single-phase

Three-phase

(Induction)Three-phase

(Sync)AC serv

DC servo

Power type

AC

AC/DC

DC

DC (including driver)/Driver

Drivers

Drivers

Drivers

Efficiency

40-60%

60-70%

70-80%

50-60%

60-80%

80%-

60-70%

50-80%

60-80%

Size

(same output)Large

Intermediate or large

Large

Small

Small

Intermediate

Small or intermediate

Small

Noise

Small

Large

Large

Small

Intermediate

Small

Large

Speed range

Narrow

Wide

Intermediate

Wide

Wide

Wide

Intermediate

Narrow

Response

Slow

Slow

Intermediate

Intermediate

Intermediate

Fast

Service life

Long

Short

Short

Long

Long

Short

Price

Low

Intermediate

Low

Low

Intermediate or high

Intermediate

High

Applications

Washing machines

Air blowers

Vacuum cleaners

PumpsCranes

Conveyors

Air conditioners

Industrial machineryCompressors

Dishwashers

Washing machinesVacuum cleaners

Electric tools

JuicersElectric toys

Electric tools

Automobile electric components

Small home appliancesAir conditioners

Dishwashers

Washing machines

Small home appliancesRobots

Small home appliances

Air-conditioning equipmentConveyors

Robots

Machine toolsPrinters

Plotters

Working machines

Judgment

Cost focused

Versatility focused

Cost focused

Cost focused

Efficiency focused

Versatility focusedVersatility focused

Performance focused

Nidec has a significant amount of experience in the fields of small brushless DC motors. The company has an 80% share of the global market for HDD spindle motors, a 60% share of the global market for DVD and other ODD motors, and a 40% share of the global market for fan motors. Nidec operates in the field of small precision motors that has experienced the most rapid shift to brushless motors. We succeeded in mass production of brushless DC motors earlier than our competitors and achieved a leading position in the market. In addition, we have held on to the world's No. 1 position by constantly introducing new technologies, such as the industry first employment of FDBs (Fluid Dynamic Bearings) that meet the needs of increasingly precise HDDs, as well as our in-house creation of design and simulation tools.

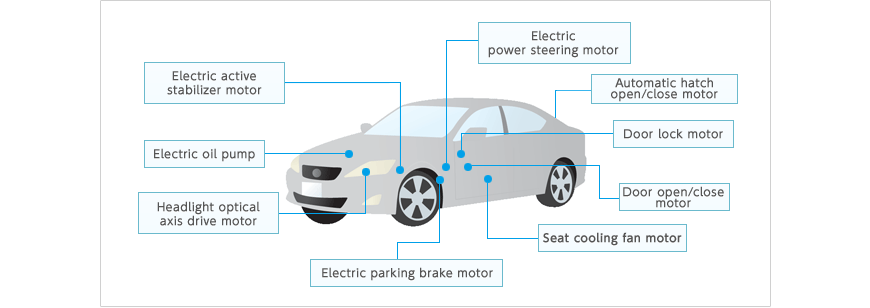

The market that is becoming the most fertile as an application field of brushless DC motors is the in-vehicle motor market. As evidenced by the power steering system whose level of fuel consumption can be improved by 3 to 5% if the hydraulic system is replaced by an electric system, the energy saving effect is very high due to the use of electric power systems. In various locations, more and more hydraulic systems are being replaced with motors. In particular, the brushless DC motor plays a leading role in function replacement where controllability is required and locations where parts are frequently used and thus long-life parts are required. The main area of application after power steering systems is compressor motors of air conditioners. Also, traction motors for electric vehicles (EVs) are a promising area for brushless DC motors. Because the system is operated on limited battery power, the motor must be highly efficient and compact so that it can be mounted in small spaces. With the experience we have accumulated so far in small precision motors, we are aiming to become the world's No. 1 company operating in the field of in-vehicle motors.